The big-block Chevy keeps getting bigger. Aftermarket blocks, dedicated stroker cranks, and array of piston sizes are pushing the good ol’ Rat to unprecedented stature–and horsepower.

In the last installment of our big-block build, CNC Motorsports in Brookings, South Dakota, assembled the bottom end of a 582ci low-deck big-block Chevy. As a quick refresher, the engine is based on a Dart Big M Sportsman block with a standard (9.800in) deck height. The reason for keeping the deck height as short as possible is the engine’s intended destination: under the hood of a ’57 Chevy pickup, where clearance is king.

A K1 Technologies 4.3875in stroker crank, 6.385in K1 connecting rods and 4.600in bore forged JE pistons complete the rotating assembly, and compression checks out at a pump-friendly 10.66:1. With the bottom end complete, it was time to finish up the engine and get it on the dyno.

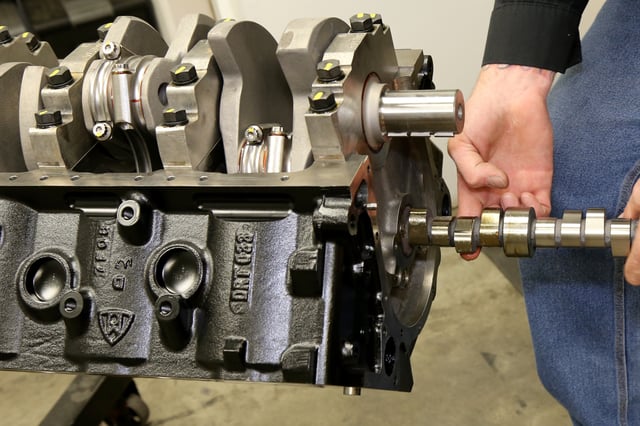

The first step was to install the camshaft. A hydraulic roller camshaft from Comp Cams with a custom, dual-profile grind was selected to maximize power and minimize maintenance. It came with the following specs: 254/262 @ .050 duration, .647-inch total valve lift, and 112 degrees lobe separation. The cam was mated to Lunati Street Performance lifters (PN 72331-16) and custom Trend Performance 1-piece, 3/8-inch pushrods made from .135in wall 4130 chromoly steel. The pushrods were measured and ordered at 7.800in and 8.700in long.

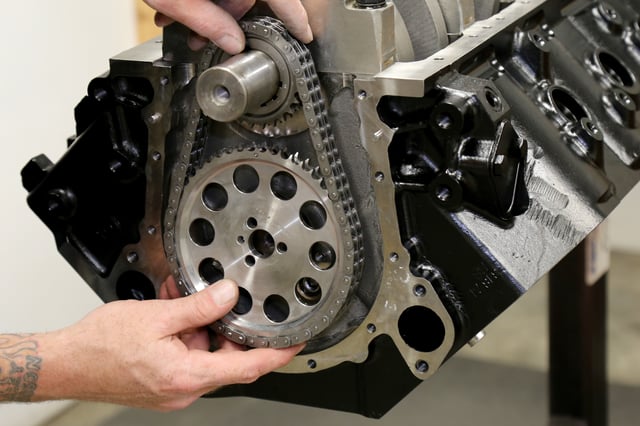

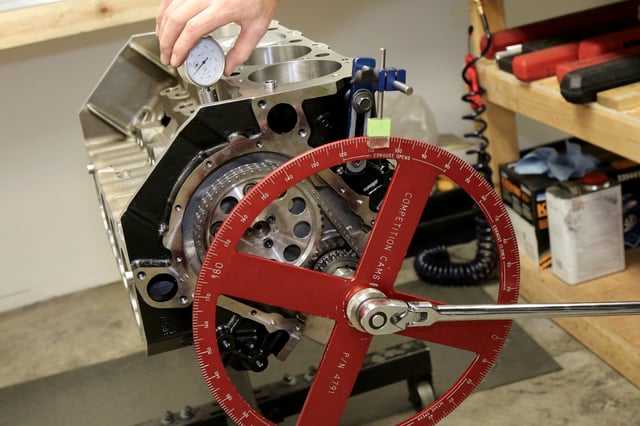

Spinning the cam is a Cloyes street billet roller timing set (PN 9-3510TX9). The 9-keyway crank sprocket allows versatile cam installation, and this cam was set with a 108-degree centerline. Protecting the timing set is a Comp Cams 2-piece billet aluminum cover (PN 212). Finishing up the short block is a 7-inch diameter Pro Race harmonic balancer (PN 34263).

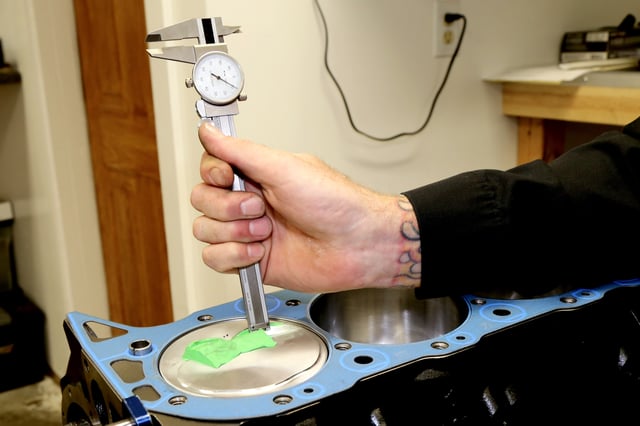

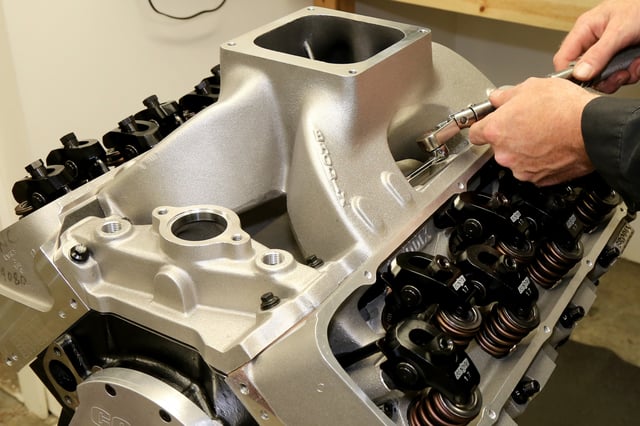

The Brodix oval-port heads (PN 2030002) feature 335cc intake ports. The intake valves are angled at 24 degrees with a 4-degree cant, and the exhaust is 15 and 4 degrees, respectively. Combustion chamber size was measured at 117cc. The heads also feature manganese bronze guides and ductile iron valve seats.

The heads were assembled with Ferrea 2.350-inch stainless steel intake valves (PN F1225P) and 1.880-inch exhaust valves (PN F6157). Both have 11/32-inch stems and are secured with Comp Cams 10-degree tool-steel retainers (PN 1731-16) and locks (PN 611-16). Total valvetrain weight is 185.8 grams on the intake side and 156.4 grams on the exhaust.

CNC Motorsports opted for Comp Cams valve springs (PN 953-16) that were installed at a height of 1.850-inch with seat pressure of 170 pounds. Open pressure was 488 pounds at 1.203 inch. Finishing off the cylinder head assemblies were Comp Cams spring locators (4778-16), Comp Cams guide plates (PN 4806-8), ARP 7/16-inch rocker studs (PN 135-7101), and Lunati 1.7:1 aluminum roller rocker arms (PN 15350-16).

The heads were installed using Fel Pro .390-inch thick steel wire-ring gaskets (PN 1057) and ARP head studs (PN 235-4702). The top end was completed with a Brodix intake manifold (BM2017-O), and an AED custom Holley Dominator carburetor. Spark is provided by MSD. Final beauty bling comes from the chrome CNC valve covers and a March Style Track CNC-machined aluminum serpentine accessory drive (PN 21255).

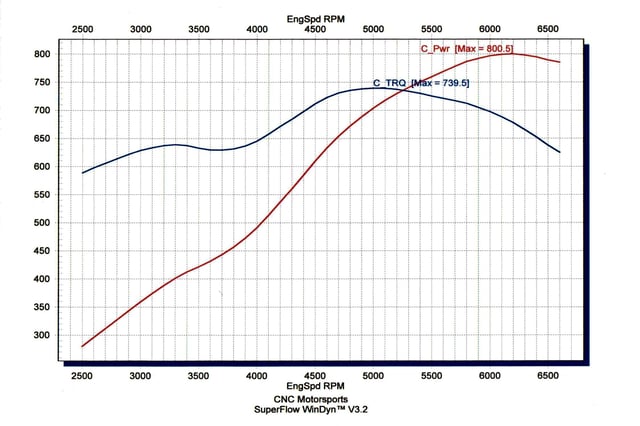

On the dyno, the engine topped out at 800.5 horsepower at 6,200 rpm, while a peak torque of 739.5 lb-ft arrived at 5,000 rpm. The engine delivered more than 600 lb-ft from 2,700 rpm well past the pull’s safety cutoff of 6,600 rpm.

Massive torque, pump-gas-capacity, and an entirely usable powerband ensures two things: a happy customer, and plenty of smokey rubber.

Sources:

CNC Motorsports; 800-341-1528; Cnc-motorsports.com

JE Pistons; 714-898-9763; JEPistons.com

K1 Technologies; 440-497-3100; K1technologies.com