Vintage Porsches are some of the most raced classics on the market and JE has introduced a new line of air-cooled pistons to support the full gamut of vintage 911 chassis.

Vintage air-cooled Porsche 911 sports cars are one of the hottest “blue chip” collector cars around. Prices have tripled, if not more for some models, as the market is further appreciating the nameplate’s rich road-racing and rallying heritage along with its distinctive and iconic silhouette. More than 1 million 911s have rolled off the assembly line since the model was introduced in 1963 as a replacement for the Porsche 356. Of those 911 production years, the air-cooled flat-six engines were used since the start up through 1998.

“We have seen this market grow faster in the last 10 years than other comparable markets,” confirms Nick DiBlasi, product manager at JE Pistons. With the surging interest in 911s, JE Pistons has overhauled its Porsche product line, ushering in new applications and applying the latest engineering techniques.

“For over 10 years we have had a smaller 911 line. The previous line included 24 total part numbers. The focus was mainly on the 2.7L, 3.0L, 3.2L, 3.3L Turbo, and 3.6L,” says DiBlasi. “The market is evolving and we have seen a huge increase in the popularity of these engines and cars being built and restored. We are constantly looking to utilize the latest technology in our products, so we felt that it was time to relaunch an expanded product line.”

JE Piston expanded the line from the previous 24 part numbers to 66 part numbers. Additional engine applications now include the early 2.0L, 2.2L, 2.4L and the 3.0L Turbo.

“We also expanded our compression ratio options and bore sizes,” says DiBlasi. “The most commonly ordered parts are for the 2.7L, 3.0L, 3.2L, and 3.6L engines, and commonly ordered in 10.5:1 and 11.5:1 compression ratios.”

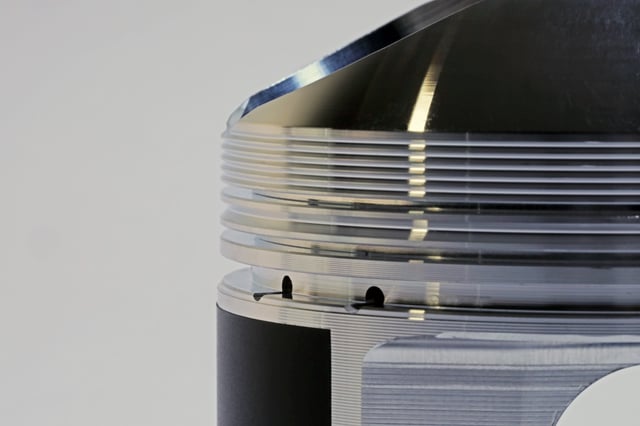

All Porsche 911 pistons are forged from 2618 aluminum alloy. A 2618 alloy has a very low silicon content that delivers a higher density rating and tensile strength. These properties make 2618 desirable in racing because the metal is more ductile and forgiving against fractures—a desirable characteristic for high boost and high operating temperatures. The higher thermal conductivity of 2618 also promotes heat transfer to the cylinder walls where the 911 cooling fins are located. On the downside.

“The 2618 is the best mix of longevity, strength and cost,” adds DiBlasi. “It is widely accepted as the industry standard for performance pistons that can handle the abuse to which our road racing Porsche customers are accustomed.”

The new JE Porsche piston line is also designed for compatibility with nickel-ceramic-coated aluminum cylinder bores.

“Since the air-cooled cylinders are aluminum, we can run significantly less clearance than an iron or aluminum water cooled block,” reports DiBlasi. “The aluminum cylinders expand considerably more and in line with the pistons; so you can run them tighter as they will both grown in diameter together. We typically run at least half of the piston to wall clearance on air-cooled applications.”

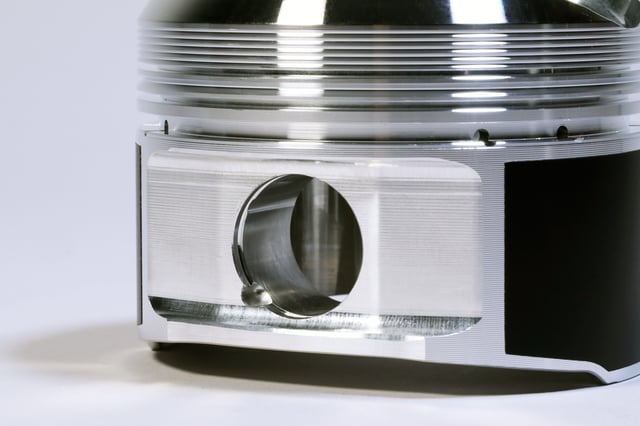

JE is leveraging technology learned from racing programs in the manufacturing of the 911 pistons. The underside of the crown is 3D machined to follow the exact pattern of the piston top. This procedure ensures a consistent thickness of the piston crown for strength while removing unnecessary weight. Other performance tricks not available in the ‘60s and ‘70s include:

- Accumulator groove machined between the top and second ring provides additional volume for residual combustion gasses that blown by the top ring. If enough pressurized gas leaks by the top ring, that pressure can unseat the top ring and hamper its sealing ability as well as inducing ring flutter and increasing wear on the second ring. The additional volume created by the accumulator groove helps reduce this pressure; thereby improving ring seal.

- Contact reduction grooves are machined between the top of the piston and the first ring land. These tiny grooves reduces the contact area against the cylinder wall should the piston “rock over.” The grooves can also reduce detonation by disrupting flame travel into the crevice area. And should detonation occur, the grooves can help protect the top ring by disrupting the waves.

- Double-broach pin oiling increases the delivery of engine lubricant to the wrist pin, which is manufactured from a stronger steel that was available to the factory when the car was assembled.

Performance engine builders will also appreciate design features that allow for more aggressive camshafts and cylinder-head modifications. “These pistons all accommodate the most commonly used oversized valves and all the commonly used bore sizes and compression ratios. Our turbo applications come with an OEM compression ratio and a few higher compression ratios as modern tuning has enabled this,” explains DiBlasi. “The naturally aspirated applications come with OEM compression and several higher compression ratios available for racing. They will include accumulator grooves on the lands, double broach oilers, upgrade wrist pins, skirt coatings, and for the first time in the Porsche line, under crown milling as a standard off-the-shelf feature.”

In race trim, some of these engines can spin upwards of 10,000 rpm. The JE Porsche pistons are designed to handle these stresses and promote power at those levels.

“In many cases our pistons will be lighter than the OEM parts for naturally aspirated applications. For the turbo parts, in some cases, our pistons will be heavier as our thicker wrist pins and robust piston design require more weight,” adds DiBlasi.

The pistons come with ring packages sized for the application. Most are 1.0mm, 1.2mm and 2.8mm with only a few others slightly thicker.

“Our Japanese-steel, gas-nitrided rings require a very smooth finish. We can provide this data to the engine builders depending on each engine and application they are building. There are variations to each build that need to be taken into consideration based on use,” adds DiBlasi.

Again, the JE line of Porsche pistons will cover the following engines used in the 911 from 1963 through 1998: 2.0L, 2.2L, 2.4L, 2.7L, 3.0L, 3.0L Turbo, 3.2L, 3.3L Turbo and 3.6L. Most applications offer an overbore of between 1 to 5 mm, and some offer an optional compression ratio. All of the pistons are designed to work with the stock crankshaft stroke and rod length.