We go under the valve covers of Subaru's latest and greatest boxer engines, the FA20 and FA20DIT, to talk tech and the right parts to take power production to the next level. Making more power starts inside your engine. Sure, you could add more boost, but typical factory internals aren’t engineered for dramatic increases in output. An engine’s theoretical performance is limited by a series of factors starting at the rotating assembly. This is among the first points of failure when discovering a stock engine’s threshold for output and stands true for just about every production engine, especially Subaru’s Boxer engines.

FA20DIT, the successor to the Aging EJ

The Subaru EJ Series Boxer engines have propelled numerous Subaru platforms in world class motorsports competition and many thousands more on the street. Delivered from the factory with anywhere from 210 to 305 horsepower (the latter powering the latest STI), these engines were notorious for oiling issues, block distortion under heavy loads and cast pistons that suffered from failed ring lands that eventually led to a blown engine.

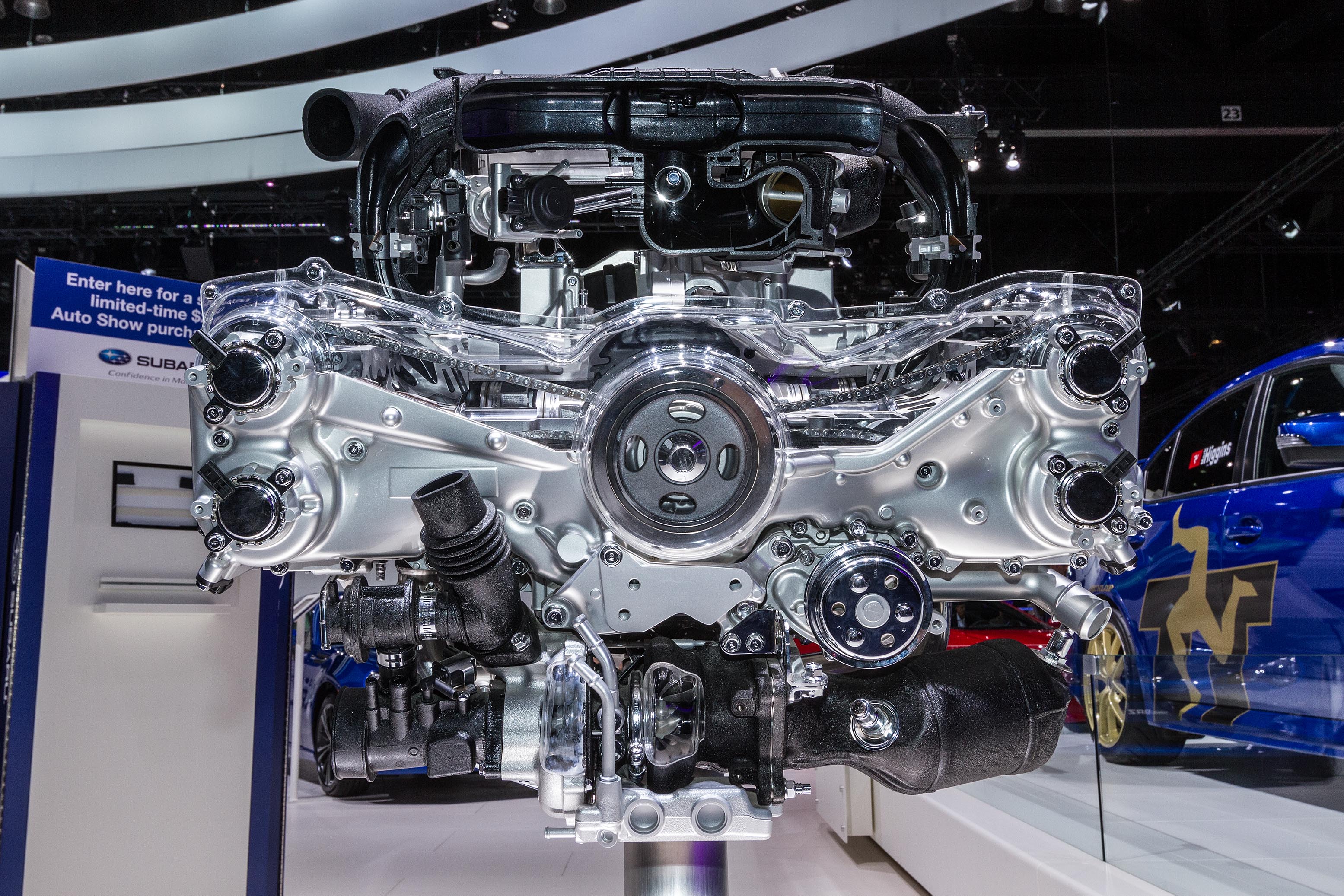

For its next generation of Boxer engine, the FA Series, Subaru made some distinct refinements to its design. Turbocharged variants of this new engine family debuted in the JDM 2012 Subaru Legacy GT as the FA20F. This engine paved the way for its American market debut as the FA20DIT (Direct Injection Turbocharged) that later equipped the USDM 2014+ Forester 2.0XT and the 2015+ WRX. This new 2.0-liter mill features a square 86mm bore and stroke dimension that results in a balanced output of 258 lb-ft torque and 268 horsepower (per the manufacturer). Its cast aluminum pistons feature a specially designed dome intended to optimize combustion of fuel delivered by the direct injection system. These pistons make the connection to the crankshaft by way of asymmetrical connecting rods designed to reduce friction and wear on the cylinder walls and the piston skirts during the compression stroke. Direct Injection fuel delivery technology lends to improvements in both output as well as fuel efficiency. To take further advantage of the Boxer’s inherently low center of gravity, Subaru engineers designed an equal-length exhaust manifold that feeds into a centrally-located, low-mount, twin-scroll Garrett MGT2259S turbocharger.

Greater Limits

Since the FA20DIT engine is still a relatively new mill, it leaves many wondering what its strengths and weaknesses are. Only a handful of owners have been willing to push their new cars to the edge of the envelope or beyond while still under warranty. The good news is that Subaru seems to have improved on its previous design, engineering what appears to be a more robust and capable powerplant. Few have reported issues relating to ring land failures or block distortion, as was the case with the EJ engine. Some premier Subaru tuners have already pushed the factory internals to approximately 380-to-400 lb-ft torque at the wheels. However, this appears to be the comfortable limit that most tuners are unwilling to push past on a stock block, as even a strong factory engine has its limitations.

Increasing A Boxer’s Potential

Eclipsing the 400 lb-ft torque level with repeatability and reliability requires fortification of the rotating assembly. This is especially true as some tuners have noted that the offset connecting rods are susceptible to bending or breaking when subjected to excess boost at lower RPM (i.e. when going to wide open throttle in a tall gear at too low a vehicle speed.) In addition to the connecting rods, the factory cast pistons are also a potential point of failure when exploring output levels more than twice that of a stock engine.

According to JE Pistons’ Director of Product Management, Nickolaus DiBlasi, “We recognized the FA Series Boxer engine’s potential especially since Subaru is utilizing this engine globally. Just like our presence in the EJ series, we wanted to fully support all the new FA series engines, making development of this piston line a natural choice. We already have a very robust selection of FA20D/4U-GSE pistons and are committed to the FA20F/FA20E/FA20DIT series as well.” After substantial engineering, development and testing, the newest JE Pistons Sport Compact offerings for the Subaru FA20DIT engine had arrived.

Cutting Edge Technology

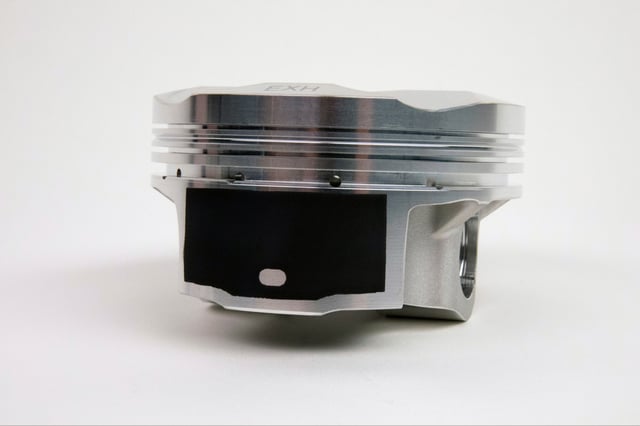

These FA20DIT pistons start with JE’s Forged Side Relief (FSR) piston design. The FSR forging features narrower pin boss and wrist pin for reduced weight, while a specialized 0.75mm wrist pin offset helps to reduce friction and excessive piston rock. These new pistons also benefit from JE Pistons’ proprietary Perfect Skirt coating, which allows them to be installed at near-factory piston-to-cylinder-wall clearances reducing piston slap and cold-start wear. 2618 alloy, favored for its ultimate strength and durability, expands and contracts more than a standard cast piston. Previously, this required looser tolerances to allow for piston expansion once warmed up. This trade-off resulted in piston slap and premature wear on the piston skirts and the cylinders during warm up. With Perfect Skirt, pistons can be installed tighter, without any risk of damaging the cylinder bore.

Why Reinvent The Piston?

When it comes to direct injection engines, the piston dome design is paramount, as it must reflect the atomized fuel toward the spark plug to be ignited. These new pistons have an FA20DIT-specific crown profile, highlighted by a 3D-milled direct injection bowl. DiBlasi explained, “We spent about two years developing the right combinations and crown profile. This design is unique to the FA20DIT and draws on the factory shape for optimal fuel atomization and combustion.”

Off the Shelf Variety to Meet Your Needs

- 2618 aluminum alloy FSR Forging with Perfect Skirt Coating

- Available in four bore sizes (86mm, 86.25mm, 86.5mm and 87mm)

- Available in two compression ratios (10.0:1, 10.6:1)

- 3D Milled Direct Injection Bowl

- Piston weight: 323-337g

- Double Broach Oilers

- 75mm Pin Offset

- 22mm 5115 hardened steel wrist pins and wire locks included

- Accumulator Groove

- JE Pro Seal piston rings included (1mm Top, 1.2mm Second, 2.8mm Bottom)

JE Pistons’ offerings for the FA20DIT starts with eight off-the-shelf part numbers, including four different bore sizes in two available compression ratios. If you’re looking for a specialized combination, JE can oblige with the fastest custom piston lead times in the industry.