When building an engine from the ground up, calculating the compression ratio (CR) is a necessary step for any number of reasons ranging from complying with racing rule books to getting a head start on the tuning.

By definition, the compression ratio is the total swept volume of the cylinder with the piston at bottom dead center (BDC), divided by the total compressed volume with the piston at top dead center (TDC). We’ll discuss the procedures and formulas for determining both the swept and compression volumes shortly; but first, let’s examine the consequences of not knowing the engine’s CR.

“Too little compression will usually result in unmet performance expectations. On the high side [too much compression] carries greater risk in tuning and potential component failure if appropriately better fuel is not used,” says Alan Stevenson of JE Pistons. “In forced induction (FI) applications, erring on the low side is much safer than pushing your luck on the high side. The tuning window widens and provides more of a safety envelope in the event of a fuel pressure or delivery problem, or even a bad batch of gas. And, if the power isn’t quite there, another pound or two of boost easily makes up the difference.”

A number of sanctioning bodies restrict the engine’s compression ratio, depending on the class or application. If the CR is not calculated correctly, then the racer could be penalized for cheating if officials discover it’s too high. On the flip side, if the CR is lower than the allowed maximum, then the racer is giving up horsepower. Even if there are no rules for CR, the racer may be restricted to a specific of fuel. Knowing the CR will provide a strong foundation for the tuning strategy.

For non-racers it’s a good idea to know and understand the data necessary to calculate the CR—especially if building an engine from scratch. When ordering pistons, for example, the company’s tech reps will need to know a number of factors to ensure the desired, or at least a safe, compression ratio can be provided. If you have a used block and don’t know the deck height, or you purchased a set of heads and don’t know the combustion chamber volume, then the potential for the types of problems mentioned by Stevenson is quite probable.

Doing the Math

In the old days, calculating the CR meant getting out the slide rule (really long time ago) or working through a set of formulas on a hand-held calculator. Today, finding online calculators that quickly spit out the results is only Google click away. But as the old saying goes, a computer is only as good as the quality of information it gets.

Measurements needed to determine the CR:

- Cylinder bore diameter

- Crankshaft stroke length

- Head gasket bore diameter

- Head gasket compressed thickness

- Combustion chamber volume

- Piston dome volume

- Piston deck clearance volume

There are a couple of high-tech calculators online that ask for even more, such as rod length and distance from the first compression ring to the top of the piston. The latter will help provide volume above the top ring, but this measurement doesn’t usually affect the final calculation significantly and is used only in very critical applications.

Online calculators generally offer a choice of entering all measurements in either inches or metric, except for the combustion chamber and piston dome volumes, which are always entered as cubic centimeters or cc.

Many of today’s aftermarket suppliers provide their respective measurements for off-the-shelf parts, which is more than half the battle in quickly determining your engine’s CR within a reasonable accuracy.

“Too many people get hung up on tenths of a point in CR but fail to understand the effects of fluid dynamics due to appropriate cam selection and phasing, for example,” says Stevenson. “If everything else is well-matched, a difference in 0.1 of ratio is negligible for anything shy of maximum effort professional racing.”

Is it Decked?

The deck height is the one measurement that the engine builder will have to make for an accurate calculation. Even with a new cylinder block, new rods and new pistons, there can be a significant difference with adding up the deck height and trying to subtract half the stroke, rod length and compression height. And if the block is used and you’re not sure of its history, there’s a possibility it could have been surfaced milled—which would alter the deck height.

“The most overlooked dimension is block height. This is critical to accuracy of compression ratio since a difference in deck clearance of .020-inch yields a significant change in CR,” warns Stevenson.

Again, the CR is calculated by dividing the total swept volume by the total compressed volume. Here’s what’s involved in determining each of those totals:

The swept volume is equal to the cylinder volume + clearance volume + piston volume + gasket volume + chamber volume. The compressed volume is equal to the clearance volume + gasket volume + piston volume + chamber volume.

All of the factors must be in the same numeric value. When calculating by hand, that’s usually in cubic centimeters or CCs. Most online calculators will automatically convert standard measurements into metric and calculate such values as the clearance volume as long as you’ve correctly entered the cylinder bore and the deck-height clearance. The online calculators can also figure out the gasket volume with the correct thickness and bore, but many gasket manufacturers will provide this information in their catalogs or on the packaging.

Identifying Speaks Volumes

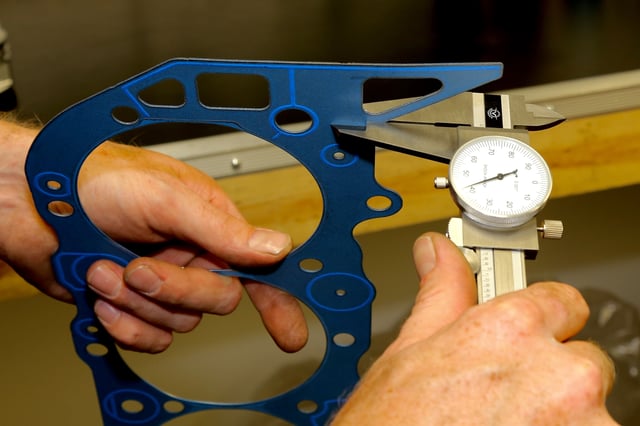

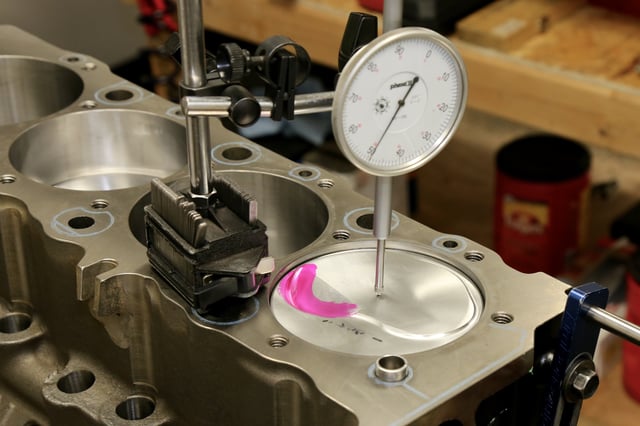

Again, performance aftermarket companies usually supply the required numbers with new parts. Piston manufacturers will provide the dome/dish volume in + or – CCs, and cylinder head companies offer their products with different volumes to help achieve the desired compression ratio. However, it never hurts to confirm with your own measurements.

“By necessity, IC engines demand fairly tight dimensional control to operate reliably so dimensional variation must be within accepted tolerances. Quality control at the manufacturing level keeps non-conforming product from being released into service,” explains Stevenson. “Nothing is ever 100 percent, of course, which is why careful measurements are standard practice for machine shops and engine builders. Assuming and not measuring almost assures an expensive and messy outcome.”

Experienced engine builders have the proper tools for taking all the required measurements, such as a bore gauge and dial indicator. The most tedious measurements are the piston volume and the combustion chamber volume. A burett, colored liquid and task-specific fixtures are required, as noted in the accompanying photos.

Big-Block Chevy Example

As an example, let’s calculate the CR for a popular big-block Chevy application. Starting with a .060 over bore (4.130-inch) and 4.250-inch stroke, the swept volume of each cylinder is 62.006ci, which equates to a 496ci V8.

Rounding out the rotating assembly will be 6.385-inch rods and pistons with a 1.270-inch compression height and 18cc dome. We’re using a seasoned block that required a bit of surface finishing, so the final deck height is 9.780. The chosen cylinder heads have 118cc combustion chambers, and the head gasket has a bore of 4.375 and compressed thickness of .040. The manufacturer says the gasket volume is 9.854cc.

With that deck height and rotating assembly, there is 0.000 deck clearance. Plugging all those numbers into an online calculator we get 10.25:1. If the engine had a new block with a standard 9.800-inch deck height, the CR would drop to 9.86:1 because there would be .020-inch deck clearance.

If calculating by hand, here’s how the formula would work with the surfaced deck model:

- Cylinder volume = 1016.094cc [(bore ÷ 2)2 x 3.1416 x stroke x 16.387]

- Clearance volume = 0.000cc [(bore ÷ 2)2 x 3.1416 x deck height x 16.387]

- Gasket volume = 9.9854cc [from manufacturer but formula is (bore ÷ 2)2 x 3.1416 x gasket thickness x 16.387]

- Chamber volume = 118cc [Value from manufacturer but could be determined and/or confirmed through measurement]

- Piston volume = -18cc [Value from manufacturer but could be determined and/or confirmed through measurement. Expressed as a negative volume because piston shape is domed. If the piston were dished or flat-top with valve reliefs, it would be expressed as a positive.]

With those numbers we add up the swept volume as 1016.094 + 0.000 + 9.985 + 118 – 18 = 1126.079. The compressed volume is 0.000 + 9.985 + 118 – 18 = 109.985. Dividing the swept volume by the compressed volume we get 10.24:1. The slight difference between the hand calculation and the online calculator is probably explained by the latter carrying out more decimals in the equation.

Once the CR is calculated, the engine builder has few options to change it without different parts or additional machining. A thicker gasket will lower the compression slightly, and a thinner gasket will boost the compression slightly. Otherwise, different pistons will have to be ordered, or the cylinder head will have to be surfaced milled to reduce the combustion chamber volume and boost the CR.

Static Versus Dynamic Compression

On a final note, these calculations will compute the static compression ratio of the engine. There is also the dynamic compression ratio to consider, which is relevant to the camshaft timing. A high-CR engine will lose some of that compression pressure if the intake valve remains open t after the piston starts the compression stroke. This is refered to as intake valve closing point.

“Physics dictates the formula used to calculate CR, and none of the constants input into that formula change with RPM,” explains Stevenson. “The only exception is the change in deck clearance due to rod stretch, particularly with aluminum rods, and component deflection such as crank flex."