The big-block Chevy keeps getting bigger. Aftermarket blocks, dedicated stroker cranks, and array of piston sizes are pushing the good ol’ Rat to unprecedented stature–and horsepower.

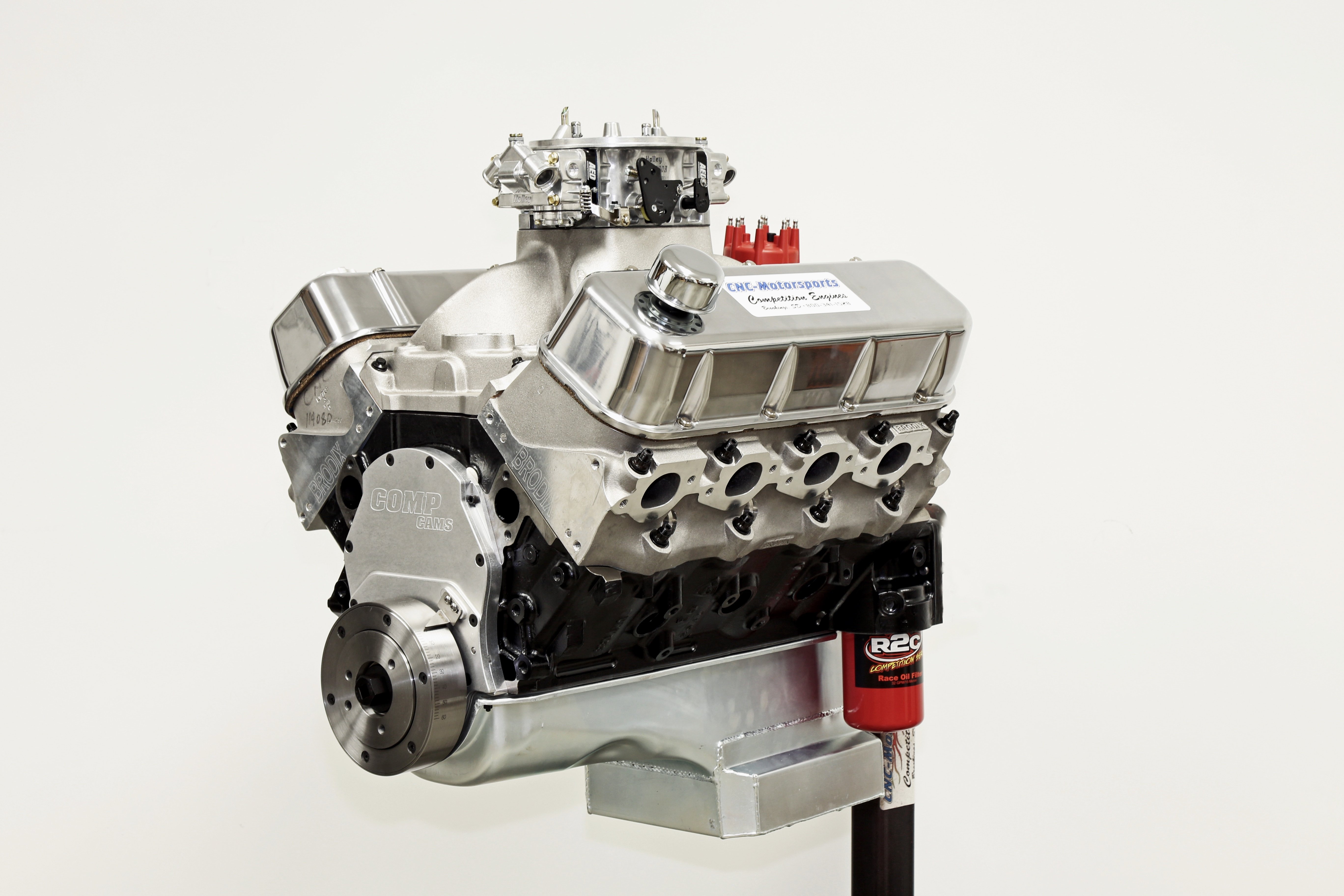

CNC Motorsports, in Brookings, South Dakota, is no stranger to big-cube builds, offering several proven BBC combinations. However, when an overseas customer wanted an 800hp big block that would run on pump gas, they knew more cubes were the only answer. Using one of their proven 540ci big-block Chevy packages as a baseline, the shop spec’d out a 582ci version that would satisfy the low-maintenance, pump-gas requirement.

“[The Customer] wanted a Pro Street-style engine for a ’57 Chevy pickup,” said Chris Carlson, a tech rep at CNC Motorsports. “He also wanted to keep it as a short-deck to avoid clearance issues, especially with the brake booster.”

Cramming 582ci into a short deck (9.800) deck height block is not a task for the faint of heart. It requires precise clearancing of the block and specially-designed stroker pistons that can survive the necessary 4.375in-stroke of a ride.

The foundation was a standard-deck Dart Big M Sportsman block (PN 31273444) with a 4.500-inch bore. It featured a priority main oiling system and splayed 4-bolt main caps–both of which should be considered requirements in this level of build.

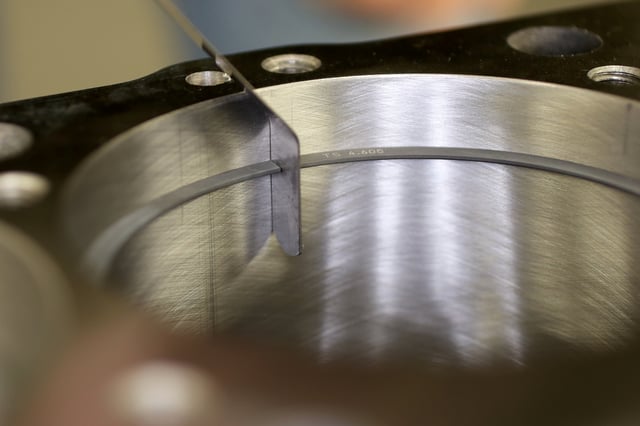

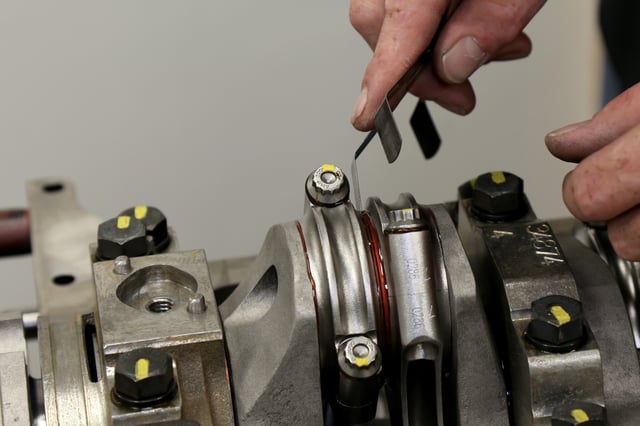

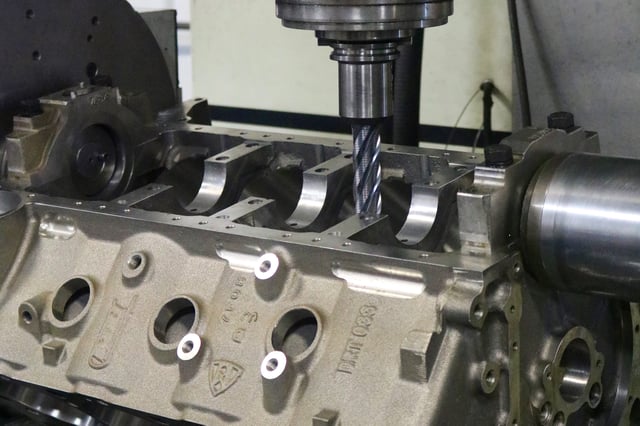

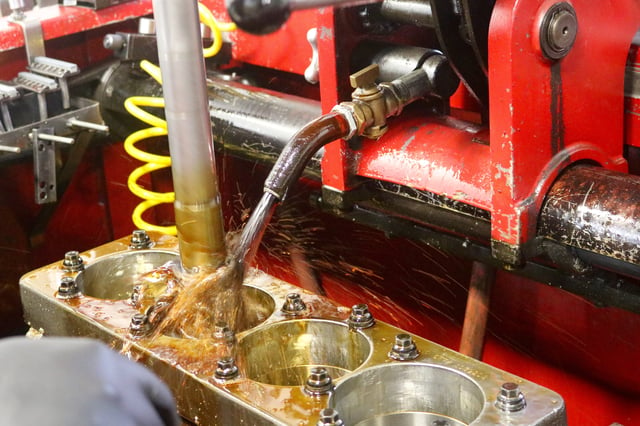

The Dart block is not clearanced for some stroker crankshafts, including the 4.375in crank selected for this displacement, so CNC Motorsports used a Rottler CNC machine to square and surface the decks in relation to crankshaft centerline, as well as machine out material on the bottom side for clearance. The block was then bored out to 4.600-inch. Jon Himley at CNC Motorsports headed up engine assembly.

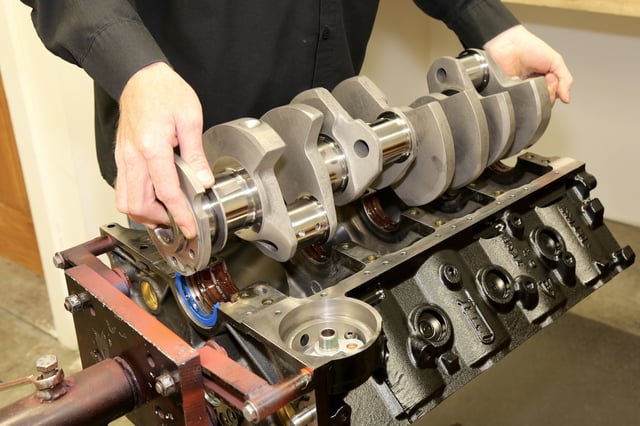

The internally-balanced rotating assembly started with a K1 Technologies 4340 forged steel crankshaft (PN 012GAG438) that comes with a 4.375in stroke along with 2.749-inch mains and 2.200-inch rod journals. K1 also supplied forged 4340 H-beam connecting rods (PN 012AG33639). They measure 6.385-inch and are secured with ARP 7/16-inch, 12-point cap screws.

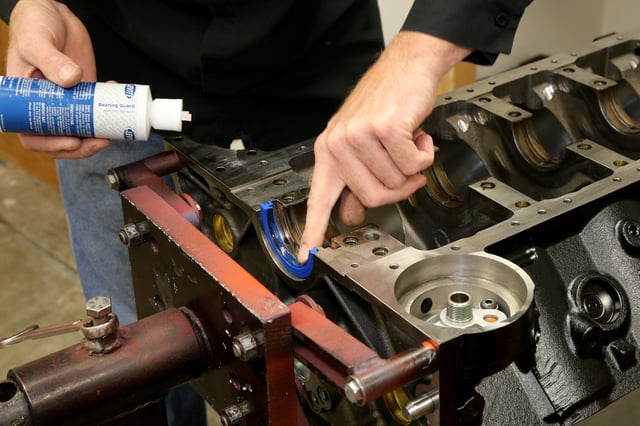

Due to the massive bore, short deck height, and long crankshaft stroke, custom JE pistons were ordered with 6cc open-chamber-style domes to provide a 10.66:1 compression ratio. The full-round-skirt pistons are designed with a 1.218in compression height to accommodate the crank’s long arm. Sealing the bores is a Total Seal ring package (PN CRG4010-5) with .043-inch ductile iron plasma moly-coated top rings, .043 conventional second rings, and 3mm 3-piece oil rings.

On the bottom end is a Melling high-volume oil pump (PN M77HV) fitted with a Kevko pickup (PN 1015) for use with the Kevko 6-quart steel oil pan (PN 1071). The pump is driven by an ARP driveshaft (PN 135-7901), and the pan is secured with a Manley hex-head, black-oxide-coated bolt kit (PN 42172) and a Victor Reinz cork gasket (PN OS30931XTC). Other finishing touches to the block include a fuel pump block-off plate (PN 839034) and oil filter adapter (PN 839049) from Pioneer.

Follow along as we detail the intricate assembly of the big-inch bottom end and stay tuned for part two where we assemble the top-end and run it on the engine dyno.

Sources:

CNC Motorsports; 800-341-1528; Cnc-motorsports.com

JE Pistons; 714-898-9763; JEPistons.com

K1 Technologies; 440-497-3100; K1technologies.com

Brodix; 479-394-1075; Brodix.com

Dart Machinery; 248-362-1188; Dartheads.com