JE Pistons offers many custom machining options which can be applied to a piston order and won't break the bank; find out what you can – and can't do before you plan your next engine build.

When it comes time to order a set of pistons, many people don't realize that JE has thousands of piston designs already created. These pre-designed pistons are offered at a much more affordable cost than a from-scratch custom piston, and can have many aspects custom-machined.

The features which can be added to your next piston order are numerous and varied. Once you confirm that your changes fit into this group, one of JE's engineers will pull up the part number for the piston, make the minor changes, and then run your piston order.

Simple Engineering Changes

The group of optional changes that are permitted to be applied to a piston order are simple enough that JE Pistons charges only $5 per piston – so across a full set of V8 pistons, each change adds $40 to the total custom piston order price. Although the order will still need to spend some time with one of JE's engineers to ensure the customer request is realistic, the engineer doesn't need to spend the same amount of time as if a complete custom piston were required for the application.

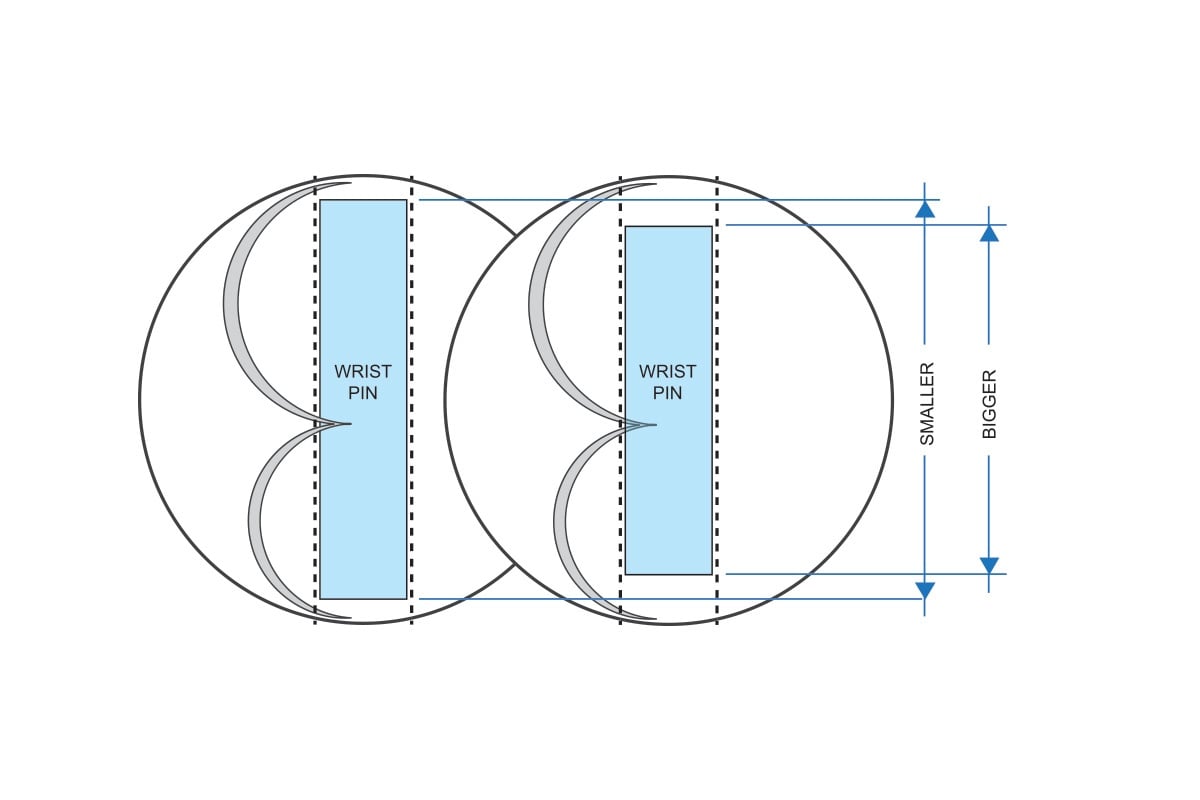

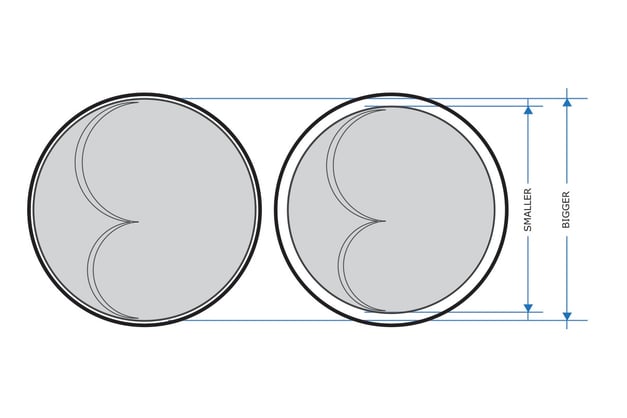

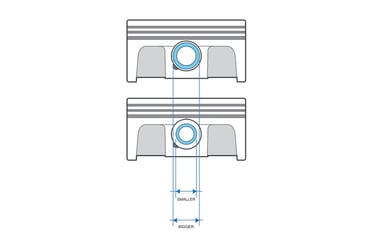

Bore Changes Of +/- .010-inch

Is there a JE shelf-stock piston that's close to your needs, but you need one with a slight overbore to clean up some cylinder wall damage? Or maybe your engine combination leaves you with an in-between piston dimension. The shelf-stock part number pistons can be easily altered slightly to overcome these conditions.

Things To Consider: Easy minor bore adjustments are possible, with a few caveats that must be taken into account during the order process. These are as follows: the piston must retain the same forging, no adjustment in compression ratio will be made to accommodate the bore change, and the bore size may not be decreased if the dimension of the first ring land height is similar to the maximum valve relief depth. Selecting this option can be useful, especially if you've owned a similar piston in the past and are simply trying to bring a tired engine back to life, or if ultimate compression ratio is not a critical concern.

JE sales will need to verify the piston is not near the end of the bore range of the forging assigned to that piston. If it is, this feature will encroach on a custom piston order since changing the forging means the piston has to be redesigned for that larger forging.

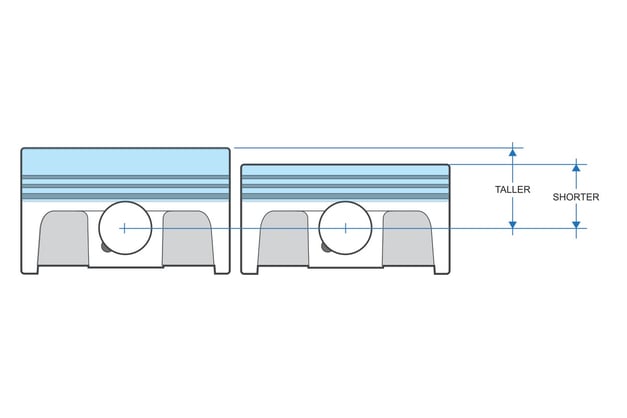

Changing Compression Distance

Piston compression height is the distance between the centerline of the pin to the flat part on the piston crown. Ideally, for the best quench characteristics and performance, the piston should be even with the top of the engine block, called Zero Deck. Depending upon the crankshaft and connecting rod dimensions you have, this may or not be the car, Compression distance is an easy change – within reason – when ordering a set of JE pistons.

Things To Consider: Compression distance can be altered plus or minus .050-inch. This particular option presents a number of challenges to be considered for the consumer. For example, decreasing the compression distance on already short pistons may require the ring stack to be altered and thus add the requirement for a rail support if the stack intersects the pin groove, while increasing the compression distance may require the removal of a rail support as the ring stack is removed from the pin bore. If the requirement for a rail support is altered due to the compression distance change, it is no longer a $5 option.

If you are looking to change the crankshaft stroke or connecting rod length, then this option may be one you want to consider. If you are using a stroker crankshaft with shorter connecting rods, or plan to use the existing connecting rods with a stroker crankshaft, then it may be possible to alter the compression distance to accommodate those changes.

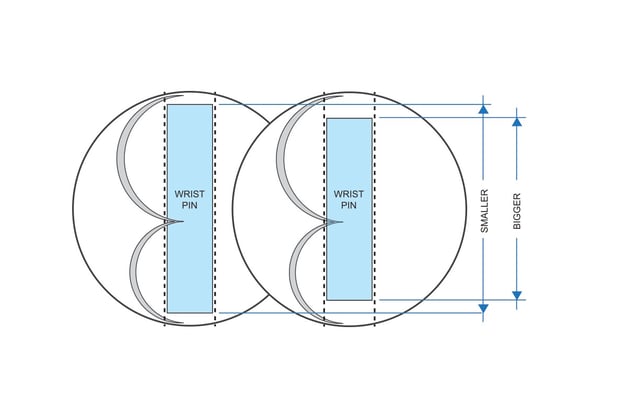

Pin Length, Diameter, Lock Type

Let's say JE makes the perfect piston for you, but the piston pin isn't as thick as you'd like it to be for your particular application. Maybe you can trim a bit of the pin length down to save weight in a light-duty application, or you like to use round wire locks instead of spiral locks – just ask when ordering, we may be able to accommodate your request.

Things To Consider: Pin diameter changes which are plus or minus one step in diameter

Things To Consider: Pin diameter changes which are plus or minus one step in diameter

– for example, from .827-inch to .866-inch pins – are included in this group of simple changes, but the diameter step change must occur with forgings where is enough material in the pin boss towers to provide the correct margin of safety. Another concern is whether the larger pin diameter will cause the pin bore to intersect the oil ring groove – if this is the case, it's not considered a simple engineering change.

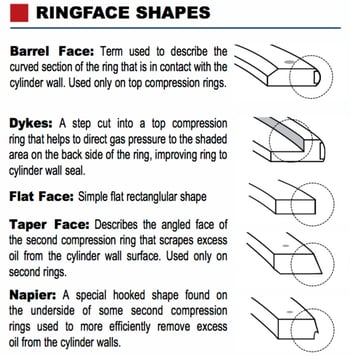

Ring Style

Different applications may work better with a different ring style – although we try to provide the proper ring set for a given application, as many of our forgings work in different applications with small changes, they'll also work with different ring styles or dimensions. These changes can be made prior to the manufacturing process.

Different applications may work better with a different ring style – although we try to provide the proper ring set for a given application, as many of our forgings work in different applications with small changes, they'll also work with different ring styles or dimensions. These changes can be made prior to the manufacturing process.

Things To Consider: A simple change in ring set part number is applicable here, as is a change in axial and radial dimensions. However, the ring set change isn't permissible if the first land height is similar in dimension to the maximum valve relief depth, as there must be enough material present between the ring groove and the valve relief. If this situation is suspected, your JE salesman may need to model this situation in SolidWorks to clarify, in which case it's not a simple change.

The Simple Engineering Change No-Nos

While many of these changes are easily undertaken, each custom piston order will go to an engineer for verification prior to the manufacturing process. The engineer will check to ensure each of the changes are permissible without any additional engineering; as long as they meet the criteria, the order will be processed. However, if the order falls under any of the below conditions, it will be kicked back as it does not fall under JE's simple change policies.

Things To Consider: Simply put, there are seven deadly sins when it comes to changes that aren't permitted in a piston order. Although the changes not permitted aren't limited to these, each change listed below is not acceptable when it comes to ordering custom JE pistons.

- Any change that requires the use of further engineering resources; i.e. SolidWorks or AutoCAD to determine the change's viability is not part of the Simple Engineering Changes group.

- Changes in dome height or dish depths which are called out dimensionally or by volume, as these changes absolutely require verification in SolidWorks or AutoCAD to ensure the piston's integrity.

- Referencing of SRP Shelf parts – custom pistons are not permitted on SRP forgings and must be moved to JE forgings and require additional manufacturing processes when referenced for a custom part

- Changes to valve relief depths and/or diameters – increasing or decreasing the depth, or changing valve relief diameters may require verification in SolidWorks

- Addition of gas ports (vertical or lateral)

- Changes in the number of pistons rings (e.g. two-ring to three-ring or vice versa) does not qualify

- No changes of forgings are permitted

There are many options available to you when it comes to ordering a set of JE Pistons, and we try to make the process as simple as possible, with an intense focus on getting you the right product the first time to support your performance goals. If you have questions, our sales people are standing by to assist you.