While off-the-shelf pistons work great for the majority of street/strip engine combinations, certain setups simply demand custom pistons. Whether it’s a 5.000-inch bore space big-block Chevy or a de-stroked, mega-RPM Bonneville motor, custom pistons are often the only option for engines that utilize a unique combination of low-volume components to push the limits of performance.

On the surface, ordering custom pistons is as easy as filling out an online order form. Sure, filling in a bunch of blanks isn’t exactly rocket science, but a variety of variables can affect critical engine tolerances, and ignoring those variables can lead even savvy enthusiasts to fill in the blanks incorrectly without even knowing it. That’s where JE Pistons’ Engineer Alan Stevenson steps in. As someone who designs pistons for a living, he’s the ideal candidate to offer valuable insight on how order custom pistons the right way.

Tip 1: When in Doubt, Ask Questions

Of the multitude of engine specifications JE’s custom piston order form asks for, many of them help establish critical dimensions and tolerances. Now, if you’re making simple design changes, like asking for a compression ratio or bore change, a full custom order form may not be required. While specs like bore diameter, stroke length, and estimated horsepower are easy enough for casual enthusiasts to fill out, more obscure dimensions—like rod small-end width and rod thickness above the pin—require measuring the parts in question with a micrometer. Furthermore, terminology like valve “free drop” may be entirely unfamiliar to the average hot rodder. That’s why it’s best to defer to a machine shop to take these measurements for you, or to seek help from a JE technician when in doubt.

Simply guessing or leaving a space blank is a recipe for disaster. “Doing your homework beforehand makes the process of filling out the form much faster,” Alan Stevenson explains. “If some of the fields don’t make sense or you’re not sure why they’re important, our technical staff can walk you through filling out the form over the phone.”

Tip 2: Measure Everything, Assume Nothing

Whether you’re building a stock or a previously rebuilt engine, never assume that an engine’s advertised specs are the same as its actual specs. Don’t assume. Measure. Stevenson advises against using ambiguous terms like “stock” and “standard,” as one person’s definition of a stock (or standard) bore or deck height can be different from another’s. “It’s not uncommon for OE’s to change an engine’s spec’s slightly mid-year or from year to year without actually disclosing those changes,” says Stevenson. Furthermore, the engine you bought at the swap meet that was supposedly bored to 4.030 inches may have been bored to 4.040 inches. “Professional engine builders know that unless they measure something themselves, they have no idea how worn out something is, or if someone else has modified a part differently from what’s described.”

Tip 3: Know your Free Drop

Perhaps the best way to avoid piston-to-valve contact is to ensure that the valve reliefs in the piston crowns are deep enough to provide sufficient clearance. However, the only way a piston manufacturer can determine the correct valve relief depth is if they’re given the correct information, in this case cam specs and valve free drop. “Cam lift, duration, lobe-separation angle, lobe centerline, and phasing all affect piston-to-valve clearance. A valve job will sink the valves farther away from the piston, while installing new seats with larger valves will move them closer to the piston,” Stevenson explains. “Due to all these variables, the best method is to measure valve free drop. This is simply how far the valve drops down off the seat before it hits a flat surface.”

Tip 4: Deck it Out

A block’s deck height is critical to calculating how tall or short a piston needs to measure above the wrist pin. Since this dimension also affects deck clearance, compression ratio, and piston-to-valve clearance, precise measurements are imperative. “The tolerances in a racing engine are much tighter than in an OEM engine,” says Stevenson. For example, although GM advertises a deck height of 9.240 inches for its LS-series small-block, it’s not uncommon for them to check in at 9.230 inches from the factory. Indicating a deck height of 9.240 inches on an order form when it actually measures 9.230 inches would yield a piston that’s .010 inches too tall. Likewise, even if you know that a block has been machined in the past, it’s still a good idea of measure the actual deck height. “If the deck surface already been machined for straightness in a prior rebuild, you need to know exactly how much material was removed by measuring the deck height.”

Tip 5: Race Pistons aren’t Street Pistons

Customers often call into tech support asking for the “best” piston, but such a component simply does not exist. “Best for what application? Do you want the lightest piston, the most durable piston, or none of the above? In this context, there’s no empirical definition to the word ‘best,’” says Stevenson. JE also warns against modeling street piston design after a race piston. Features like gas ports, for instance, work remarkably well in race engines by improving ring seal and increasing power. However, since they’re intended for race applications with limited duty cycles, gas ports can lead to premature wear in street engines. “Don’t assume that a piston designed for a maximum-effort professional race engine is well suited to a street car. Nothing could be further from the truth.”

Tip 6: Be Honest

Let’s face it. Enthusiasts tend to exaggerate when the subject matter at hand involves projected horsepower output and quarter-mile ET’s. Unfortunately, overly optimistic performance predictions can lead to a piston design that doesn’t quite match an engine’s real-world use. Why deal with the increased cold start-up noise associated with a rugged 2618 alloy forging when the lower expansion rate of a 4032 alloy is much better suited for an engine that was supposed to get a big shot of nitrous but never did? “Be honest about what environment the pistons will actually be operating in and leave the design to us. We have had customers that try to play piston engineer with disastrous results,” Stevenson recounts. “Trust the experts. Piston design and manufacturing is the only thing JE Pistons does, and we’re the best in the business.”

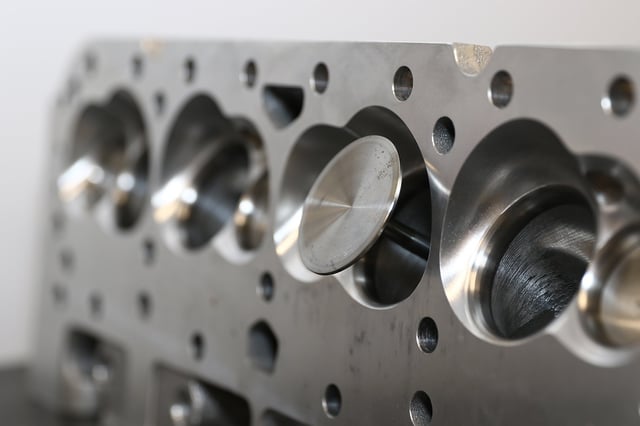

Tip 7: Know Your Heads

As cylinder heads continue evolving into more specialized pieces of hardware, combustion chamber design and valve placement continue to evolve as well. That puts the burden on piston manufacturers to get the design of the piston crown just right. Likewise, it also puts the burden on customers to relay the correct cylinder head specifications to the piston manufacturer. “Be absolutely sure of exactly which cylinder heads you have. This is particularly important with domed pistons,” Stevenson advises. “Make sure to ‘cc’ the combustion chambers to get an exact measurement of the chamber volume. This ensures that compression ratio calculations are correct. The best option is preparing a mold of the actual chambers. Instructions can be found here.

Tip 8: Don’t Cheap Out on Wrist Pins

Wrist pins take some serious abuse. Focusing too much on piston design and ignoring the role of the wrist pins can lead to costly engine failure in a hurry. “Whether it’s a $5,000 build or a $50,000 build, it’s all junk if a wrist pin breaks,” Stevenson quips. “Standard pins are fine for most applications up to about 90-100 horsepower per cylinder. Beyond that, the extra $50-$100 you pay for superior pins is very cheap insurance.”

Tip 9: Trust the Experts

There’s absolutely nothing wrong with taking pride in doing things yourself, but even the greatest engine builders on Earth rely on the expertise of piston manufacturers to deliver a quality product up to their exacting standards. “Custom pistons are some of the most intricate and detailed components in an engine, so there is tremendous value that comes from working with experienced engine builders, machine shops, and distributors. In addition to supplying other related engine components, they can provide priceless insight and expertise. Machine shops and engine builders have the right measuring tools for spec’ing out custom pistons, so that saves you money. Having them order custom pistons on your behalf also decreases the risk of making a costly mistake during the ordering process.”

Tip 10: Used = Modified

While there are many great deals to be had on used parts, the unknown variables that come with them can throw a monkey wrench into spec’ing out the correct piston. Milling down a set of cylinder heads, performing valve jobs, and decking a block each change critical dimensions and tolerances that affect piston design. “Assume that everything purchased used has been modified at some point. That’s why it’s best to take precision measurements of everything,” Stevenson advises.