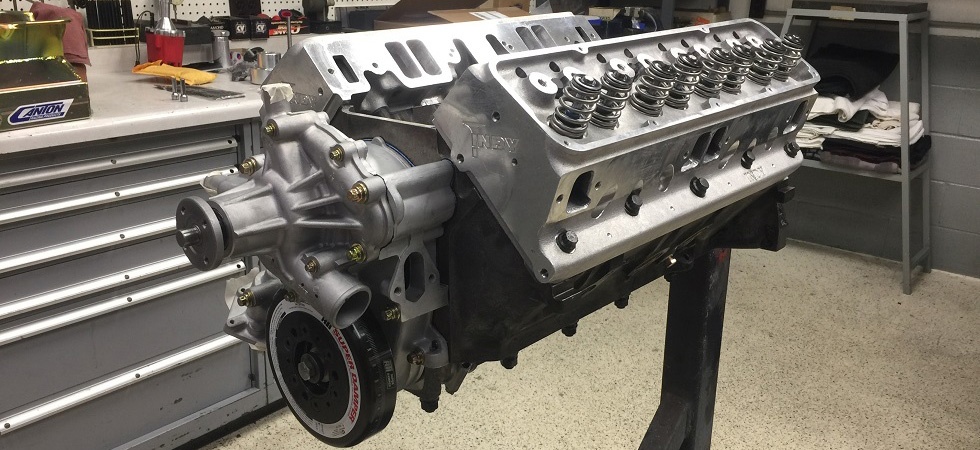

A couple of interesting talking points were revealed about the AMC 390 V8 that engine builders should note if they tackle such a vintage platform. Most important, the oil system leaves much to be desired, so Rhyne Competition Engines out of Gary, Indiana, came up with solutions that improve the lubrication when the shop built this 525-horsepower 442ci stroker engine.

Destined to power a Pro Touring-style 1969 AMX owned by Bruce Rask, the project started with the car’s original block, and that’s about the only factory part that carried over. The block was cleaned, Magnafluxed and align-honed before being bored .030 over to 4.195 with Sunnen equipment. It was also surfaced to a 9.175-inch deck height, which resulted in a true zero-deck-clearance for the pistons.

“The block feeds oil only from the front and then the oil works its way to the back,” says Rhyne general manager Mike McKinney. “As it goes through each lifter bores it loses volume and pressure. The rear lifters don’t get as much oil as the front.”

Rhyne tapped into the front galley and plumbed an internal braided-steel line to about two-thirds of the way to the rear of the engine. The team also tapped off the rear galley to provide for a more accurate oil-pressure reading. Finally, Rhyne fit the lifter valley with screens over the oil drain-back holes.

“In case there’s a rocker arm or lifter failure,” adds McKinney.

The block was also treated to Dura-Bond cam bearings, Clevite P-Series main bearings and ARP main studs that allowed final torque of 110 ft-lb.

Most of the displacement increase comes from a forged-steel, 4-inch stroker crankshaft manufactured by K1 Technologies. In a slight hybrid design, the rod journals were ground for Chevy-sized 2.100-inch Clevite H-series bearings (original size was a beefy 2.250-inch). Stock 390 crankshaft stroke is 3.574-inch. Clearances were set at .003-inch on the mains and .0024-inch on the rods.

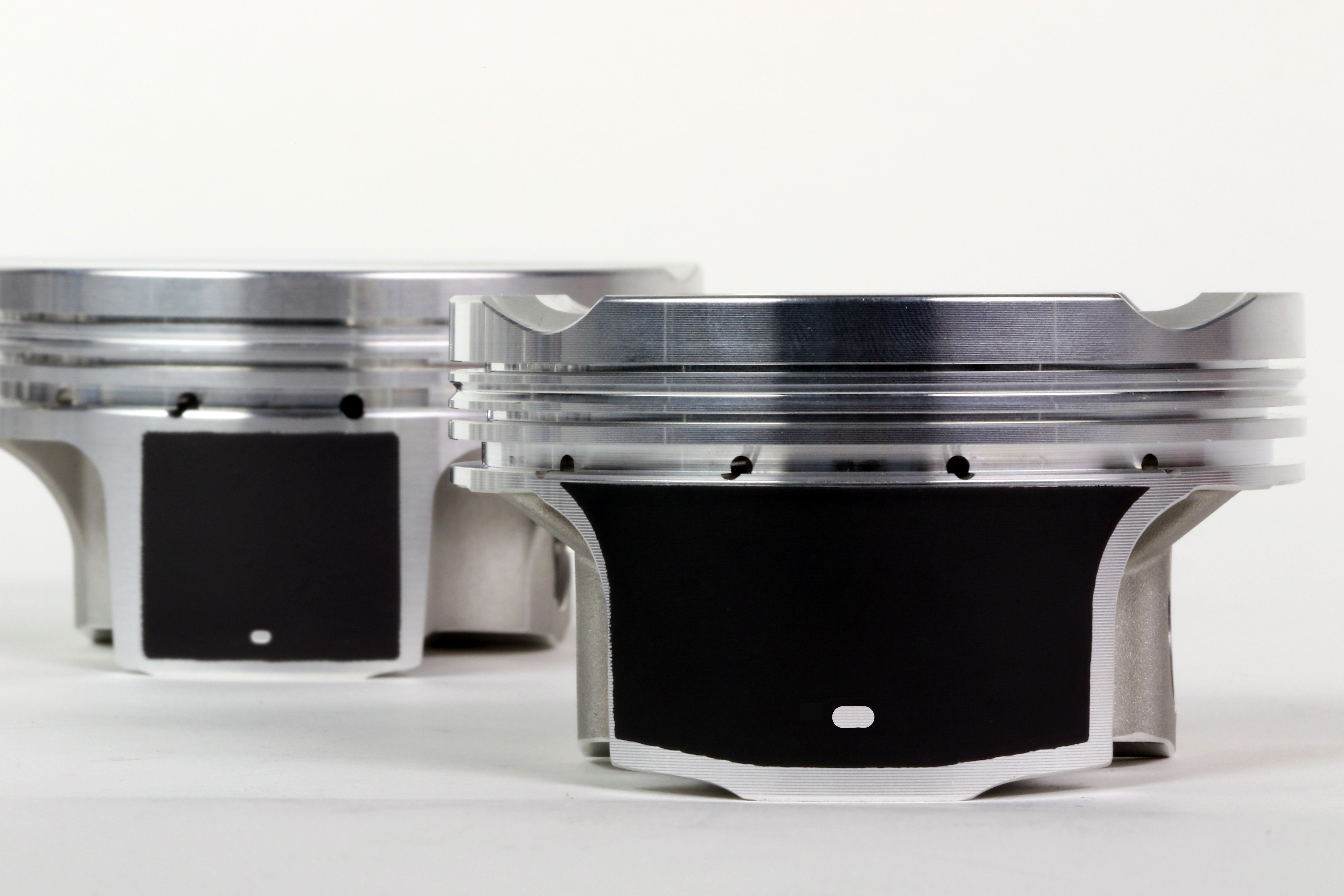

With the 5.850-inch Molnar H-beam rods, the JE Pistons aluminum-alloy dished pistons were ordered with a 1.325-inch compression height. That distance still provided enough room for a 1/16-1/16-3/16 Total Seal ring package. Final compression ratio is 10.2:1, which reflects the factory numbers and allows pump gas. The dished pistons also gave the team a generous .175-inch piston-to-valve clearance on the exhaust side and .170-inch on the intake. Additionally, undercrown milling helps reduce weight from the rotating assembly.

Securing the pistons to the rods are JE 2.950-long wrist pins that are held in place with Spirolox. For the record, the piston weight is 495 grams while the wrist pin comes in at 140 grams. The rods, which are fitted with ARP 2000 bolts, tip the scales at 612 grams. Adding in the rings and locks, the final rotating bob weight is 1,837 grams.

Continuing to upgrade the lubrication system, Rhyne installed a Canton 8-quart road-racing-style oil pan with baffles to help control oil starvation at the pickup during cornering. Instead of relying on the internal stock pickup system to feed the oil pump, Rhyne installed an external feed line to supply the oil pump mounted on the factory timing cover. Rhyne then modified the oil pump with a Melling performance kit.

“This way we’re putting oil directly to the pump,” says McKinney. “We felt it was a better way.”

The timing cover also protects a Rollmaster timing set that turns a dual-pattern Comp Cams hydraulic roller camshaft. Specs with 1.6:1 Comp rocker arms are .555/.577 lift with 236/248 degrees duration at .050. Lobe separation is 113 degrees. The cam works with Lunati lifters and Comp 7.850-inch long, 5/16-inch diameter pushrods.

There aren’t many cylinder head choices for the AMC 390 engine, and even fewer for a one with an additional 52 cubic inches.

“Except all-out race heads,” says McKinney. “We went with the Indy cylinder head because it offers 235cc runners.”

Indy’s 401-SR cylinder head also offers a 61cc, high-quench heart-shaped combustion chamber. It was fitted with Manley 2.100-inch titanium intake valves and Ferrea 1.650-inch stainless-steel exhaust valves. Other improvements include ARP 7/16-inch rocker studs, Comp valve springs (340-pound open pressure) and Comp Cams titanium retainers. Fel-Pro gaskets are squeezed between the block and heads with ARP head bolts.

Topping off the engine are a MSD billet distributor and a Indy single-plane intake manifold that was prepped by CFM Competition Cylinder Heads. For break-in and dyno testing, Rhyne used a carburetor. However, the engine was delivered with a FiTech Go EFI-4 600-horsepower self-tuning fuel-injection unit.

Finally, Rhyne fabricated the V-belt front accessory drive using CV Products pulleys and a KRC power-steering pump and reservoir.

“The owner wanted to keep everything tucked in nice and tight,” remembers McKinney. “The original power-steering pump was high and wide.

From the factory, the AMC 390 was rated at 315 horsepower at 4,600 rpm with peak torque at 425 lb-ft at 3,200 rpm. Again, for the dyno tests the engine sported a 750 cfm Braswell carburetor drinking 110-octane fuel. Timing was set at 34 degrees, and 2-inch Doug’s headers were bolted in place. The engine was swept from about 3,000 rpm up to 7,300 rpm. It pulled more than 400 lb-ft of torque through all the lower rpm range and up to 6,500 rpm, peaking at 520.6 lb-ft at 4,900 rpm. Horsepower topped out at 525.3 at 6,100 rpm.