Before a single machining operation is performed, the perfect aluminum alloy must be selected. 2618 and 4032, the two most prolific piston materials, have a long list of differences that make them best-suited for specific applications.

It seems the more you know, the more there is to learn. For the average guy – stock pistons are cast, race pistons are forged and the rest isn’t really important. In a Peter Pan world that might be enough, but it turns out that technology offers choices and it pays to know the players better by reading the score card. In the case of forged pistons, it comes down to a slightly more complicated choice of the better of two alloys. Too much information might be awkward in certain situations, but when it comes to pistons, more details are always a good thing.

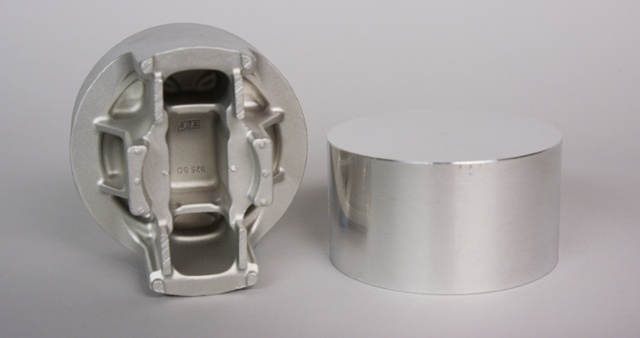

We must start this discussion with a little basic metallurgy. Our approach will be focused entirely on forged pistons. These pieces of art are not pure aluminum. Instead, performance pistons come in two distinctly different alloys.

First let’s address the 4032 alloy represented by most of the JE SRP (Sportsman Racing Products) line of pistons. This alloy is created with a high silicon content – a full 12 percent. The addition of silicon greatly reduces aluminum’s expansion rate, which means that with this single addition to its mixture, the piston can now run with tighter cold clearances.

Element Breakdown

|

2618 |

4032 |

||

|

Aluminum |

93.7% |

Aluminum |

85% |

|

Copper |

2.3% |

Silicon |

12.2% |

|

Magnesium |

1.6% |

Magnesium |

1.0% |

|

Iron |

1.1% |

Copper |

0.9% |

|

Nickel |

1.0% |

Nickel |

0.9% |

|

Silicon |

0.18% |

|

|

|

Titanium |

0.07% |

|

|

This additional silicon content, also improves this alloy’s durability, again making it a great street engine choice when subjected to thousands of low-load road miles. Besides the typical wear you might see along the piston skirts, the most critical position for ultimate performance is actually in the ring grooves. A 4032 piston will maintain the proper ring groove clearance and seal for more miles traveled.

4032 alloy can be used in performance and even competition applications with excellent results. However, its reduced ductility does make the alloy less resistant to cracking with extreme impact loads such as detonation or unforeseen physical contact than would be the case with a 2618 alloy. But don’t let that scare you. According to JE’s Director of R&D Dave Fussner, there have been Pro Stock teams that have experimented with 4032 pistons because the alloy is slightly lighter.

Piston Alloy Characteristics

|

Material Characteristics |

4032 |

2618 |

|

Tensile Strength |

55,000 psi |

64,000 psi |

|

Yield Strength |

46,000 psi |

54,000 psi |

|

Fatigue Endurance |

16,000 psi |

18,000 psi |

|

Modulus of Elasticity |

11,400 psi |

10,400 psi |

|

Melting Point |

990 - 1,060 F |

1,020 – 1,180 F |

The main difference with a 2618 alloy, as represented with the JE race piston line, is its very low silicon content. This makes a 2618 piston much more malleable, which offers advantages under high-load, high-stress applications such as with power adders (superchargers, turbochargers, or nitrous oxide).

See the Full Line of JE Pistons

However, this lower silicon content also means the piston has a greater linear expansion rate, which must be compensated with greater ambient piston-to-wall clearances. A 2618 piston will expand 15 percent more than a 4032 version. This, as we’ve mentioned, is the reason a 2618 piston requires more clearance and as a result will be slightly noisier when cold as opposed to a comparable 4032 forging.

Despite the differences in piston-to-wall clearances when cold, once the pistons reach operating temperature, both the 2618 and 4032 alloys would will have similar running clearances.

The 2618’s lower silicon content also makes the piston slightly less wear resistant compared to the 4032. For pistons used in competition applications, this isn’t a major consideration since they will be replaced in the search for ultimate power long before significant wear is introduced.

2618 Alloy Pros and Cons

| Pro | Con |

| Stronger | Piston noise (when cold) |

| More Ductile | Slightly higher wear rate |

| Better fatigue life | |

| Excellent High Temperature Strength |

However, if wear is a consideration with either a 2618 or 4032 piston, JE offers an optional hard anodizing coating process for the ring groove and pin bore areas. The anodizing process is not plating, penetrates the surface while also adding a layer of oxidized aluminum that is much harder than the parent aluminum.Given that ring land wear is directly related to ring seal, this can be a popular option for endurance engine applications as a way to improve cylinder sealing efficiency as evidenced by reduced leak-down rates.

4032 Alloy Pros and Cons

| Pro | Con |

| Excellent Wear Rate | Less Ductile |

| Quieter (Especially Cold) | Less Fatigue Resistance |

| Slightly Lighter | |

The 2618 alloy is renowned for its excellent high-temperature strength. This makes it the preferred choice for outright racing – especially in extended wide-open-throttle competition. It can also be a superb choice for a serious street power application. And, if long-term ring groove wear is a consideration, the anodizing option is a great way to extend its performance.

Each alloy offers different characteristics but at some point, the benefits of the stronger, more race-oriented 2618 alloy makes the decision rather simple if your intent is to go racing. If you find yourself straddling the alloy fence, the good news is it’s difficult to make a bad decision.

Piston alloy is really just one of many decisions you will need to make on your way to assembling your next engine. But armed with the right information – that engine has a superb chance to make great power and put a smile on your face all at the same time.