Wrist pins have one of the hardest jobs in an engine, carrying tremendous loads from combustion, then trying to slow down rapidly accelerating pistons and send them back the other direction. Proper wrist pin oiling is essential to keeping them alive! We explore all of the different styles and their uses.

It’s hardly breaking news that engine output has drastically increased in the last decade or two. With digital control over fuel, spark, and especially with advancements in power adders like turbos and supercharging, this is the golden age of horsepower. Power levels now in excess of 2,000 hp from sub-400ci engines means radical increases in cylinder pressure, which concentrates the load on innocuous parts like the wrist pin.

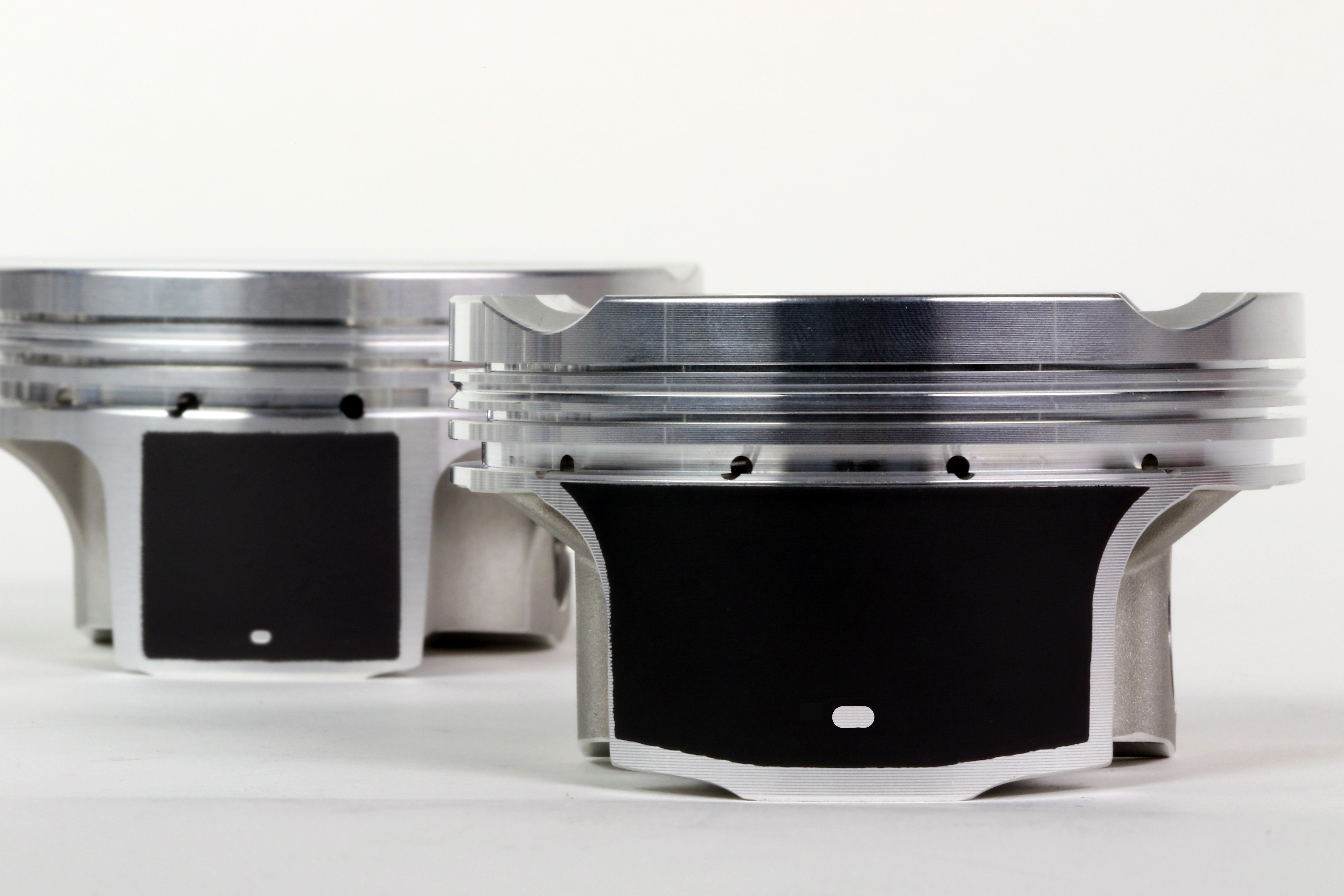

JE Pistons offers multiple wrist pin lubrication options specially designed to excel in all types of high-horsepower racing and performance applications.

Wrist Pin Oiling Styles

- Single forced pin oiler – A drilled oil channel from the back of the oil ring groove to the pin bore on each side.

- Double forced pin oiler – Two oil channels from the back of the oil ring groove to the pin bore on each side.

- Double broach oilers – Two broaches on the pin bore that allow oil to lubricate the pin on each side.

- Bottom pin boss oilers – Holes drilled through the pin bore from the bottom side of the pin tower to lubricate the pin.

- Cup oilers – A scallop of material cut out of the pin bore to reservoir oil

- Annular grooves – A longer groove of material cut out of the pin bore to reservoir oil.

Each of these lubrication options offer advantages and if we interviewed 10 engine builders we would get that many different takes on what constitutes the ideal approach. All of this is based on what we could call application-specific needs. Director of Product Management for JE Pistons, Nick DiBlasi, says the standard approach most often used on shelf pistons is either single or double forced pin oilers or the double broach technique. DiBlasi mentioned that broach oiling – pulling oil in from the end of the pin from slight elongations of the end of the wrist pin bore, is what the OE’s are now beginning to incorporate into their engines.

Contributors that can foment potential wrist pin oiling are often subtle, such as reducing internal oil leaks. Production engine builders must consider aluminum blocks that house steel hydraulic lifters that are tasked with starting in -40 degree F weather, so details like lifter bore clearance are forced to increase – which contributes to increase in oil flow. All this extra oil tends to be hurled around the inside of the engine, which eventually finds its way to the wrist pins.

But competition-bred and high output street engine builders are increasingly conscious of reducing internal windage in an effort to reduce parasitic power loss. This also reduces the amount of oil that might find its way up to the wrist pins. On the plus side, many engine builders are now using dedicated piston oilers (jets) both to help reduce the piston crown temperature and to put more oil in the wrist pin area.

Wrist Pin Durability

There are several conditions that affect wrist pin durability. Oiling is obviously the main concern, but cylinder pressure is another huge component as it increases the load on the wrist pin. Adding stroke and higher engine speeds are two other candidates that will add load to the piston. A longer stroke requires the piston to move quicker per crankshaft revolution, which makes its directional reversal from bottom dead center to top dead center much more violent.

One of the first considerations even with stock pins is the clearance to the connecting rod. A typical pin fitting clearance is within the range of 0.0008- to 0.0010-inch to the connecting rod. This clearance is a double-edged sword since tighter operating clearances increase the load carrying capacity but reduce oil flow. Noted engine builder David Reher suggests that increasing this clearance improves the oil flow, especially in highly loaded situations since the pin does not deflect evenly. With a slightly larger clearance, there is more chance oil can move across the pin and prevent galling or transfer of material.

DiBlasi says “Pin clearance varies on its use, rpm, hp, duty cycle, and various other aspects. We have customers who request pin bore to pin clearance of .0005-inch to over .0025-inch. Each engine builder has their specific requirements and tricks that make them unique.”

Reher also offers that engine servicing is an excellent opportunity to inspect the pins – especially those on the even-numbered or passenger side bank of the engine. He says this side of the engine is often the first to show signs of distress since that bank will see less oil due to oil scrapers and other windage control efforts.

If engine inspection reveals that the wrist pins are experiencing distress, the classic response would be to add a heavier wall pin. But adding mass may not necessarily be the solution. If maintaining a low overall piston reciprocating mass is a consideration, the addition of high-strength material for the pins is where the selection process should start.

Based on all this, pin durability is equally application specific. DiBlasi explains it this way. “We have various pin materials depending on the customer’s application. Drag racers prefer through-hardened steel pins for their high impact resistance while circle track racers prefer a case-hardened steel with high surface hardness. This enables a higher rpm threshold and longer life. Additionally, coatings can be added to these materials for reduced friction and extended life.”

Creating proper lubrication in highly stressed areas like the wrist pin also means addressing the actual lubricant. There have been huge advancements in lubrication science just within the last five to seven years. Up until recently, synthetics were based on what are called PAO’s or polyalphaolefins that offer substantial improvements over conventional oil in their ability to not lose viscosity (thin out) as the oil temperature increases. The latest version synthetics are called mPAO’s or metallocene PAO’s that once again improve the lubricant’s viscosity index. This means this new base oil is far more stable under high temperature, allowing the engine builder to potentially reduce clearances while maintaining oil’s film strength that will reduce friction. So investigating the advantages of mPAO-based synthetic oil is another way to potentially improve wrist pin durability.

You wouldn’t think that a short piece on wrist pin lubrication would have covered such diverse topics as engine building science, metallurgy, and even tribology (the study of oil) but that is the new normal to get the facts needed to ensure the survival of 21st Century engines. Researching these topics might get a bit technical, but if that’s what it takes to keep your engine alive while it cranks out over 2,000 hp, then it’s a small price to pay to keep all those spinning parts happy.