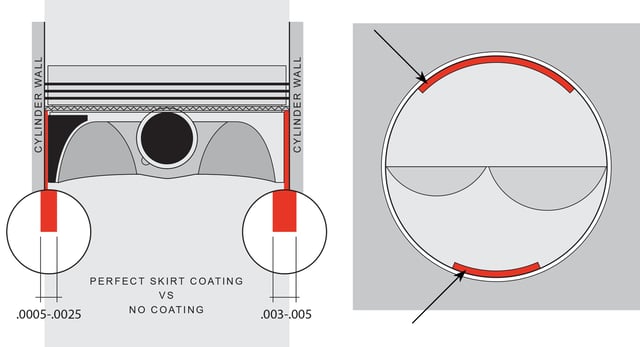

JE's revolutionary, patented Perfect Skirt coating makes piston slap, false knock, and cold-start wear a thing of the past. For the first time ever, 2618-alloy pistons can be installed with piston-to-wall clearances near that of an OEM piston!

For official instructions on how to install JE Perfect Skirt–coated pistons, click HERE!

Depending on the type of engine and the accuracy of any number of engineering studies, between 10 and 20 percent of an engine’s total energy output is lost through friction. And of that amount, up to half can be tied up in the piston skirts and rings.

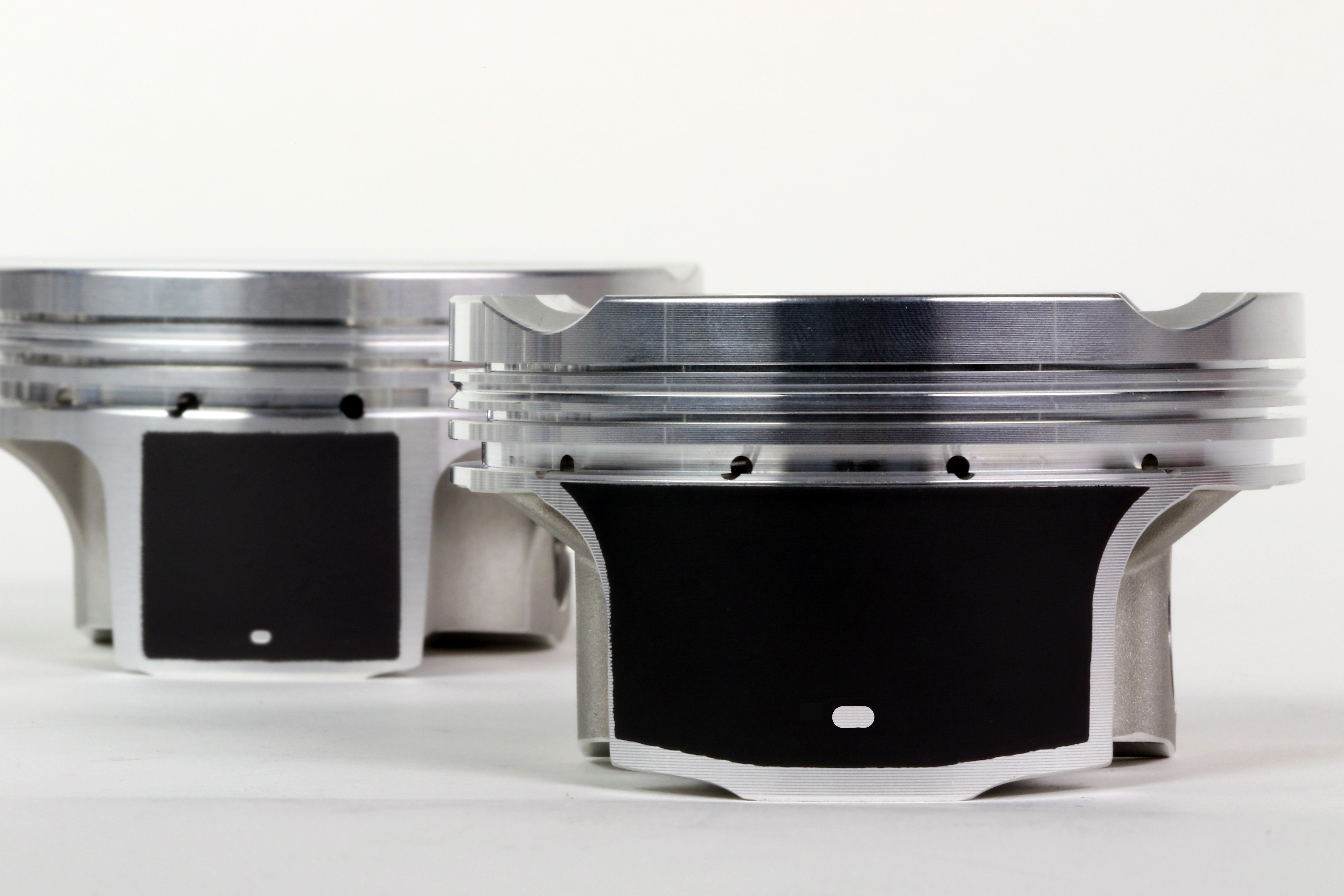

Even at the low end of those numbers, it just makes good power sense to reduce friction and wear around the piston whenever possible. To that end, JE Pistons is introducing a new solid-film-lubricant coating called Perfect Skirt. The advanced technology—including the formula, tooling and application process—was developed in house, and the goal was to offer a new coating technology that delivers a double-barrel benefit to the engine. This coating will come standard on many popular engine applications.

First Perfect Skirt Applications

- Subaru EJ20, EJ25, FA20

- Mitsubishi 4G63

- Nissan VR38DETT

- Toyota 2JZ-GTE

- Chevrolet Gen IV LS and Gen V LT

- Volkswagen/Audi 1.8T and 2.0T TSI/TFSI

- Modular Ford (4.6L, 5.4L and Coyote)

“The motivation was to develop a robust skirt coating that could be applied and bonded thicker and allow the forged piston to be installed at the same or less cold clearance than a cast piston, as measured on the coating,” says Nick DiBlasi, product manager at JE Pistons.

The applications listed above are the first shelf-stock parts to get the new Perfect Skirt coatings, and JE will be announcing several other applications in the very near future. Perfect Skirt will join the plethora of stocking pistons as a running change, so part numbers will remain the same.

Perfect Skirt is a solvent-based coating that is permanently applied to the piston skirts in a 3-stage bonding process. Unlike many coatings, it is not a temporary layer for break-in. It will stay bonded to the piston throughout its service life.

“This is not a typical spray-on type application,” says DiBlasi. “The skirt panels are transformed from a bare aluminum running surface to a permanently bonded solid-film running surface.”

Perfect Skirt will complement JE’s other well-known skirt coating called Tuff Skirt—which is typically is used on custom orders where the numerous options available change the piston foundation too much to allow proper application of the coating.

“Perfect Skirt requires tooling designed to fit each piston family and is used on our catalog shelf part line, which we designed specifically for it,” explains. DiBlasi.

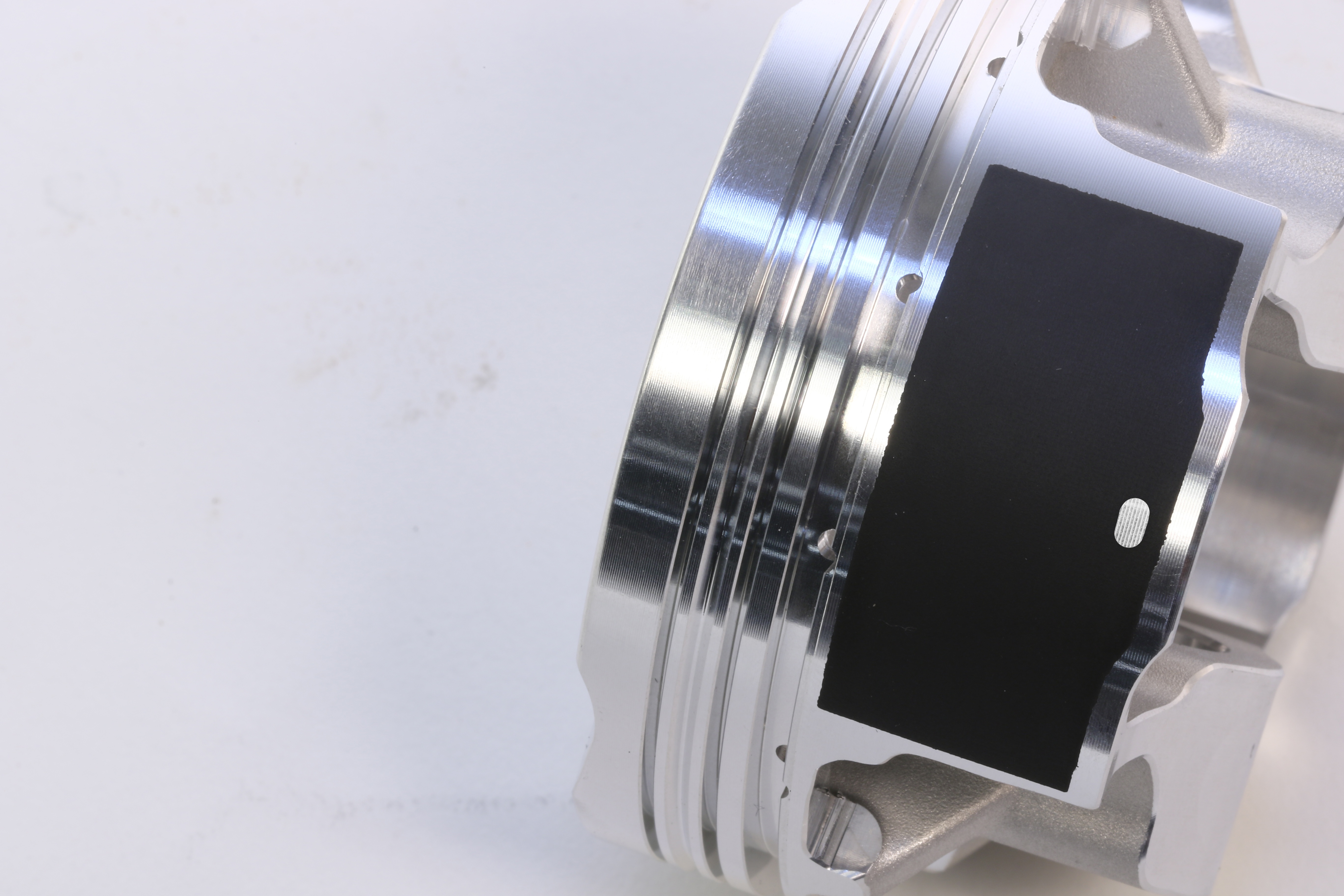

Perfect Skirt is not a spray-on coating. It is installed with proprietary tooling in a 3-step bonding process. This includes two curing steps for maximum adhesion.

Perfect Skirt is not a spray-on coating. It is installed with proprietary tooling in a 3-step bonding process. This includes two curing steps for maximum adhesion.“That is an unsatisfactory method and yields unsatisfactory results. We invested considerable time and resources in the development of the patented Perfect Skirt coating method,” says DiBlasi. “The Perfect Skirt coating formulation has the unique ability to automatically precisely fit itself to the specific cylinder in which it’s installed.”

When an engine is first fired up, the piston coating in contact with the cylinder wall will quickly adjust to a precise form and provide minimum running clearance. “At this point, the coating has settled into a uniform and equalized pattern, providing very low friction and quiet operation throughout its service life,” adds DiBlasi. By reducing clearances, the Perfect Skirt coating reduces cold-start wear and more importantly the chance of false knock readings in late-model engines.

“Many high horsepower street applications utilize OEM ECUs and can register false knock when having a larger piston to wall clearance,” explains DiBlasi. “Perfect Skirt solves this by providing the correct operating clearance and having substantially quieter operation.

When the computer detects knock (false or real) it pulls ignition timing out of the tune to protect the engine, but also robs the driver of power. In the past, many would use a higher-silicon-content aluminum to reduce piston expansion and noise, however it came at the expense of ultimate piston strength. Perfect Skirt blends two major components to have the best of both worlds. We have the quiet operation and tighter piston-to-wall clearance of higher silicon materials with the high-strength benefits of a 2618 alloy.”

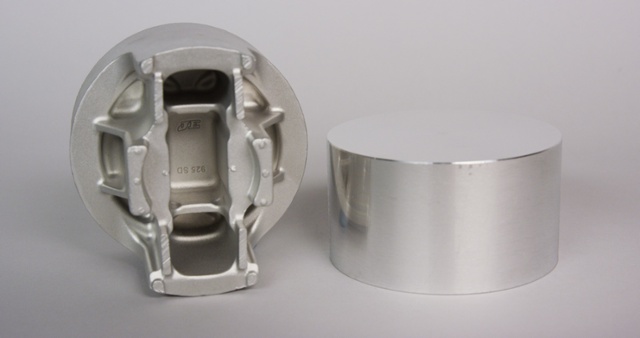

Unlike the processes used to apply other piston coatings, Perfect Skirt is not sprayed on the piston. “It’s an advanced screen-printing processes that provides thickness ac curacies to within several microns,” says DiBlasi. The application process starts with a thorough cleaning of the piston, then a fluorescence inspection is made to ensure a pristine surface. The piston is then mounted on proprietary mechanized equipment located in a climate-controlled room within the JE manufacturing facility. After the coating material is applied to the skirt, the piston moves through two thermal treatments—the second of which is a bonding and curing operation.

One of the more interesting footnotes to the overall manufacturing process using Perfect Skirt coating is that the actual diameter of the bare piston is not adjusted to accommodate the coating. In other words, the engine builder need not concern with calculating a new running clearance that takes into account the self-fitting dynamics of the Perfect Skirt coating.

The piston will always expand when brought up to operating temperature. So, a JE piston designed for a 4.000-inch bore should be installed in a cylinder with a 4.000-inch bore. The Perfect Skirt coating is design to take up much of the clearance designed into the piston. In other words, it will reduce the clearance but there is no chance of scuffing the piston or cylinder wall.

“It is important to note that skirt of the piston with the Perfect Skirt coating system will measure larger on top of the coating than the same piston measured bare without the coating,” stresses DiBlasi. “This is the desired, intentionally produced Perfect Skirt condition. The bore diameter of the engine should not be increased to account for the Perfect Skirt coating thickness. Oversizing the cylinder to accommodate the Perfect Skirt coating thickness will nullify the benefits of the Perfect Skirt coating technology. Special break-in procedures are not required with this coating.”

Perfect Skirt is a game changer and that will forever alter the way piston design is perceived. All compromises are off the table, leaving only the absolute best part for the job at hand. “We feel that this will benefit our customer immediately," said DiBlasi.

How to Install JE Perfect Skirt Pistons

For even more information on installing pistons with Perfect Skirt, Click HERE!