Stay on top of the engine technology curve and come get educated on the latest engine platform - Direct Injection.

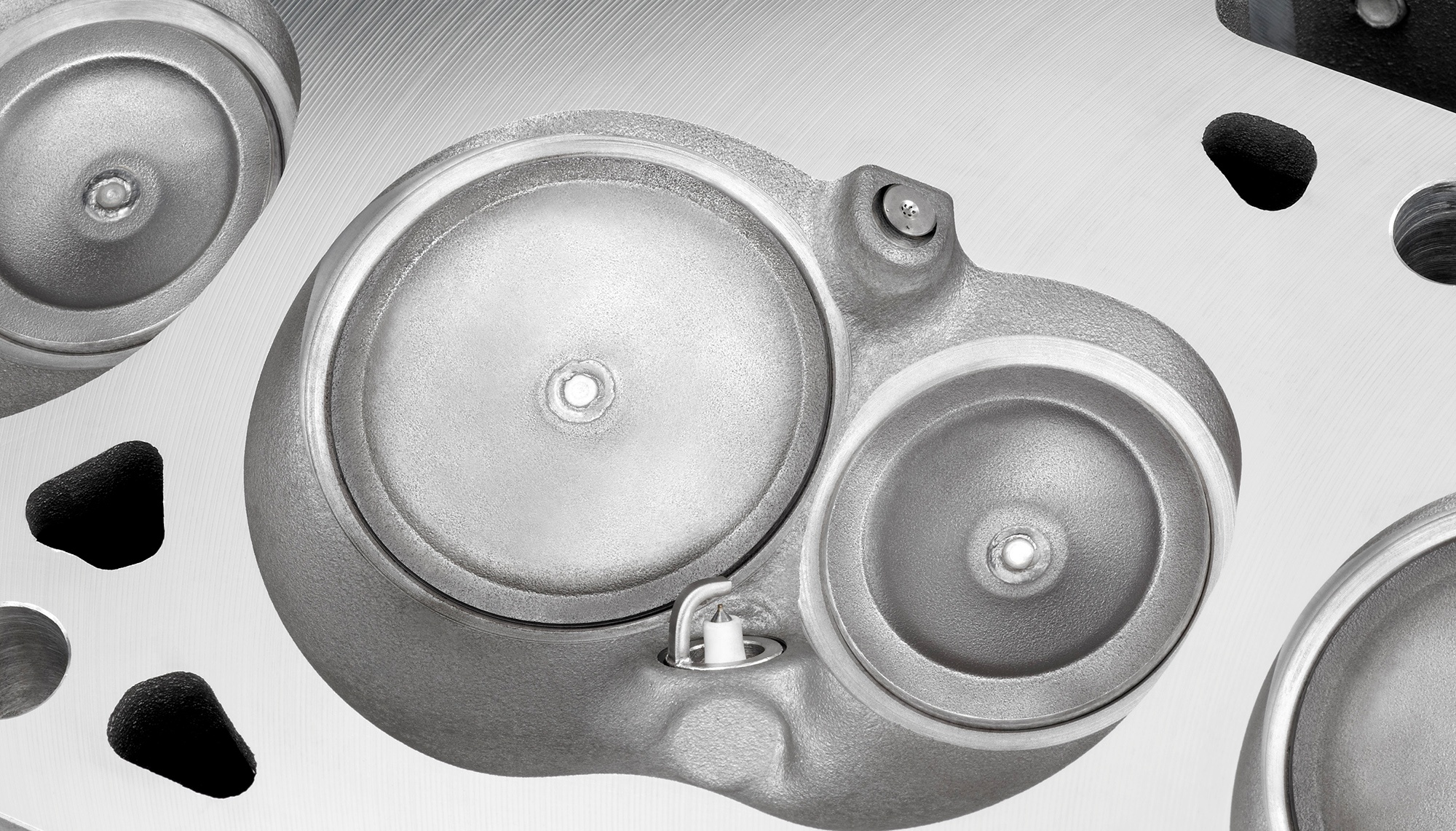

Lead Photo: Here’s an LT1 cylinder head that has a similar looking bowl design to an LS. The big difference in the fuel injector that sits opposite of the spark plug.

Originally Featured in Hot Rod Magazine.

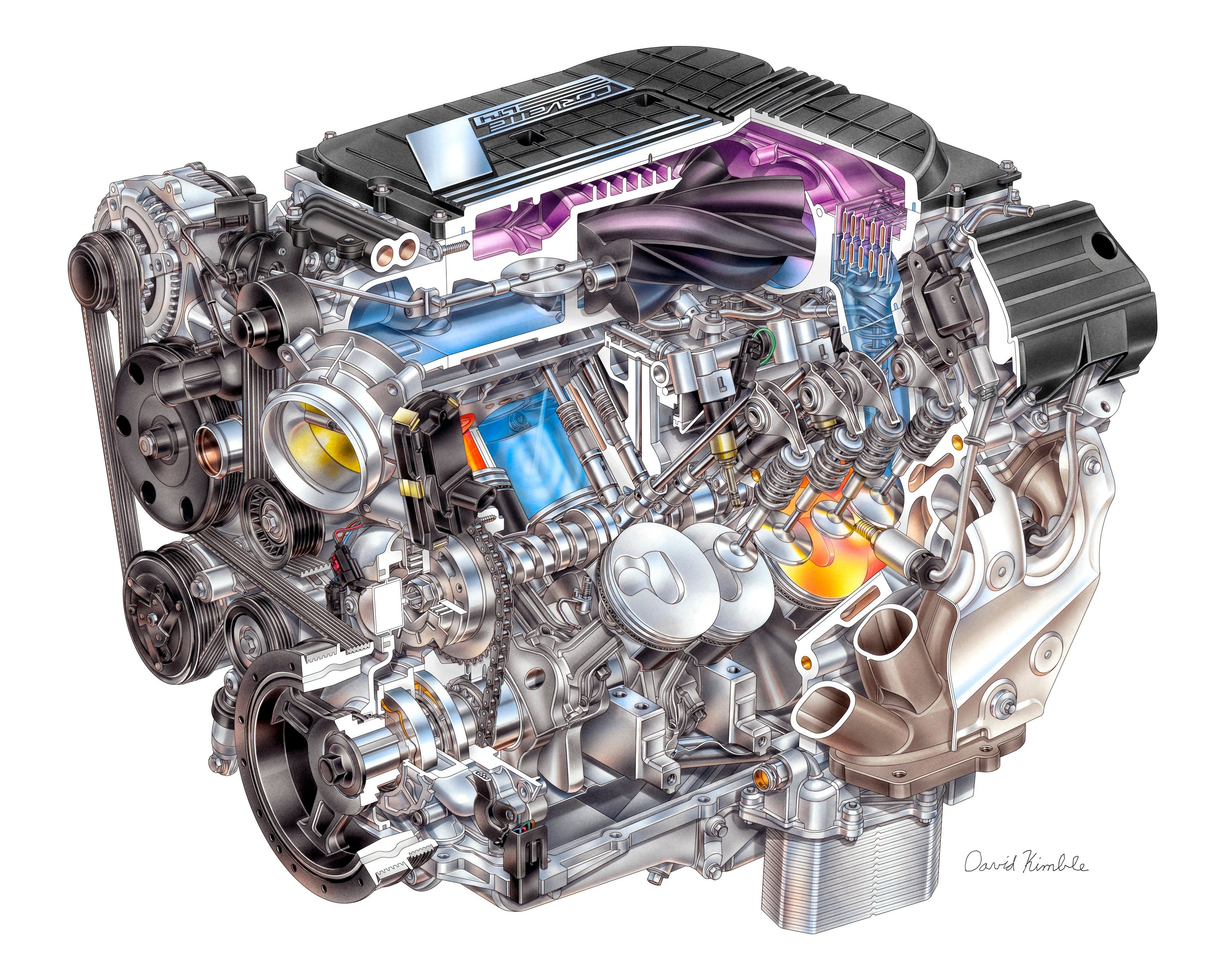

There’s a new acronym that is now floating around the performance industry - GDI - it stands for gasoline direct injection. Among the domestic production engines that have jumped heavily into the GDI segment is the new LT1 and LT4 engines but Ford was the first to take on a spark-ignited gasoline direct injected engine with its series of EcoBoost engines that debuted domestically in 2010.

So what exactly is GDI and why could it be the future for all production gasoline engines? It’s all about combustion efficiency. For decades, a majority of engine building attention has focused on tuning with intake and exhaust plumbing and improving volumetric efficiency. But eventually, all this effort comes down to physical act of combustion. A crucial portion of this process requires placing the correct amount of fuel in the combustion chamber as efficiently as possible. In the time just after dinosaurs ceased to roam the earth, carburetors were the fuel mixing device of choice. Then came multipoint electronic fuel injection (MEFI) but even that now is considered rudimentary compared to injecting fuel directly into the combustion space.

GDI’s advantages are multi-fold. First, even with multi-point fuel injection, a certain amount of fuel ends up deposited on the walls of the intake port upstream of the intake valve. This fuel eventually contributes to combustion, but not necessarily at the proper time or in the best condition. The condition of fuel is as important as its ratio to the oxidizing air. Liquid fuel does not burn well. Instead only vaporized fuel contributes to the combustion process.

An extreme example of this can be found in Top Fuel racing. Nitromethane is highly combustible, but nitro’s flame speed isn’t much different from gasoline. However, Top Fuel engines routinely employ ignition timing in excess of 50 degrees before TDC. The reason for this incredibly early ignition lead is that only 10 percent of the fuel in the chamber is vaporized. The rest remains a liquid. This is because these engines operate at very close to a 1:1 air-fuel ratio! The cylinder demands the spark light 50-plus degrees BTDC to initiate the burning process early enough to produce enough early heat to eventually vaporize and burn the large amount of fuel in the chamber.

Gasoline engines operate with drastically leaner air-fuel mixtures, but the concept is still the same – only vaporized fuel will burn completely. With direct injection, the fuel can be introduced into the cylinder at pressures exceeding 2,200 psi so that at least a greater portion of the fuel will quickly vaporize. Even so, direct injection at very high pressures demands changes in the combustion space.

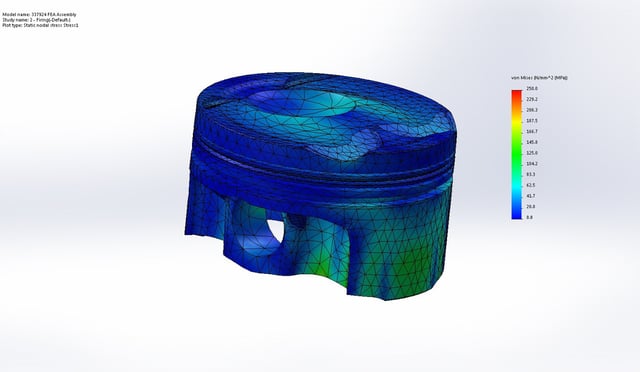

You may have noticed that GDI engines generally employ a much different piston crown design than comparable non-GDI engines. The concept is to use a trough or depression in the piston crown that will direct the fuel once it has been injected. The focus of this trough is to aim a stratified or directed charge of a relatively rich mixture fuel at the spark plug to initiate the combustion process. Once ignition occurs, then the remaining fuel can be combusted to produce an overall efficient mixture.

Generally, the high-pressure fuel injector is located near the center of the cylinder. Research indicates that late injection of the fuel into the cylinder is beneficial for emissions and fuel efficiency with the piston near TDC. A centralized trough in the piston crown tends to re-direct the fuel spray upwards toward the exhaust side of the chamber near the spark plug. This generates something the combustion research engineers call turbulent kinetic energy (TKE). A higher TKE tends to support improved thermal efficiency where more of the fuel is used in combustion.

There are several advantages to this approach. First, it reduces the chance for detonation since the fuel is concentrated more toward the center of the combustion space near the spark plug. Knock generally occurs from end gases with sufficient fuel that auto-ignite near the end of the combustion process. By concentrating the fuel around the spark plug, this greatly reduces the need for increased ignition lead time. By introducing the fuel microseconds before the required spark timing, pre-ignition is virtually eliminated and the engine benefits from less negative work. This is significant since advanced ignition timing demands that the engine must expend negative work to compress the initial onset of combustion from advanced ignition timing.

The Aftermarket Approach

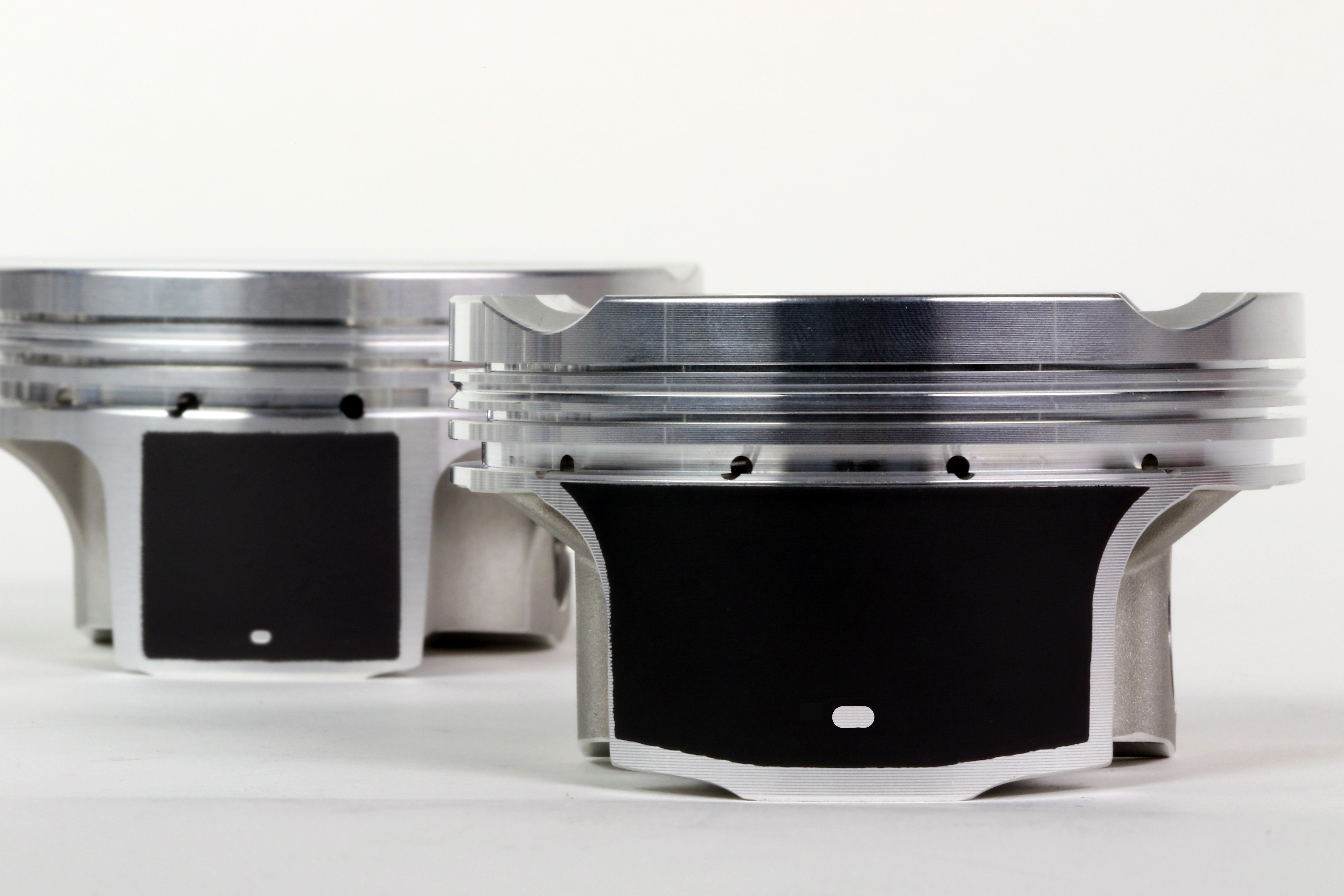

According to JE Pistons engineer Clayton Stothers, other than the piston crown design, there is not a significant difference in piston configuration between a forged GDI piston and one designed for carbureted or EFI engines. Obviously strength is a considerable concern in order to accommodate the higher cylinder pressures that will generate more horsepower. JE Pistons’ Forged Side Relief FSR) design synergizes added strength with weight reduction for a superior piston design.

One additional benefit of the proper piston top design is that more of the fuel is concentrated in the center of the combustion space offering less fuel potentially trapped near the cylinder’s outer circumference. Fuel that tends to collect around the outer edge of the combustion space often does not burn and therefore does not contribute to making power. These unburned hydrocarbons also then just exit with the exhaust and contribute to reduced thermal efficiency.

GDI engines consistently reduce the amount of fuel that is trapped around the piston’s circumference, which means that – especially at part throttle – that this improved combustion efficiency allows the engine to run at much leaner air-fuel mixtures which improves fuel efficiency. The net result of this is there are examples of current GDI engines running at air-fuel ratios in excess of 30:1!

Again because of this improved combustion efficiency, GDI engines can also run higher static compression ratios. As an example, GM’s LT1 takes advantage of the GDI design to push static compression to 11.5:1. JE’s EcoBoost turbocharged V6 pistons sports an impressive 10.0:1. Conventional multi-point EFI engines would not dream of running a turbo with that high of a static compression on pump gasoline. Of course, the advantage to this higher compression is additional power as one full point of compression is generally accepted to deliver around three to four percent additional power for a normally aspirated engine.

JE’s line of EcoBoost V6 pistons take all of these factors into account when designing a performance piston. Even the largest bore pistons reduce weight with a 3.661-inch bore piston still at barely 400 grams while still maintaining superb piston durability. The offset pin design reduces piston noise and the included 1.0/1.2/2.8mm ring package also contributes to reducing parasitic friction losses.

Noted turbocharged engine builder Kenny Duttweiler is currently experimenting with an Ecoboost 2.3-liter engine and as he told Hot Rod magazine, he expects that with a larger turbocharger that the engine could potentially make as much as 1,100 hp.

So we can safely assume that GDI engines will continue to be the current trend in performance engines for the near future. Bosch projects that a fully 20 percent of all production passenger car engines will rely on gasoline direction injection by the year 2020. With that as an incentive, JE Pistons will continue to offer performance pistons to meet the new challenges of the future of high performance.